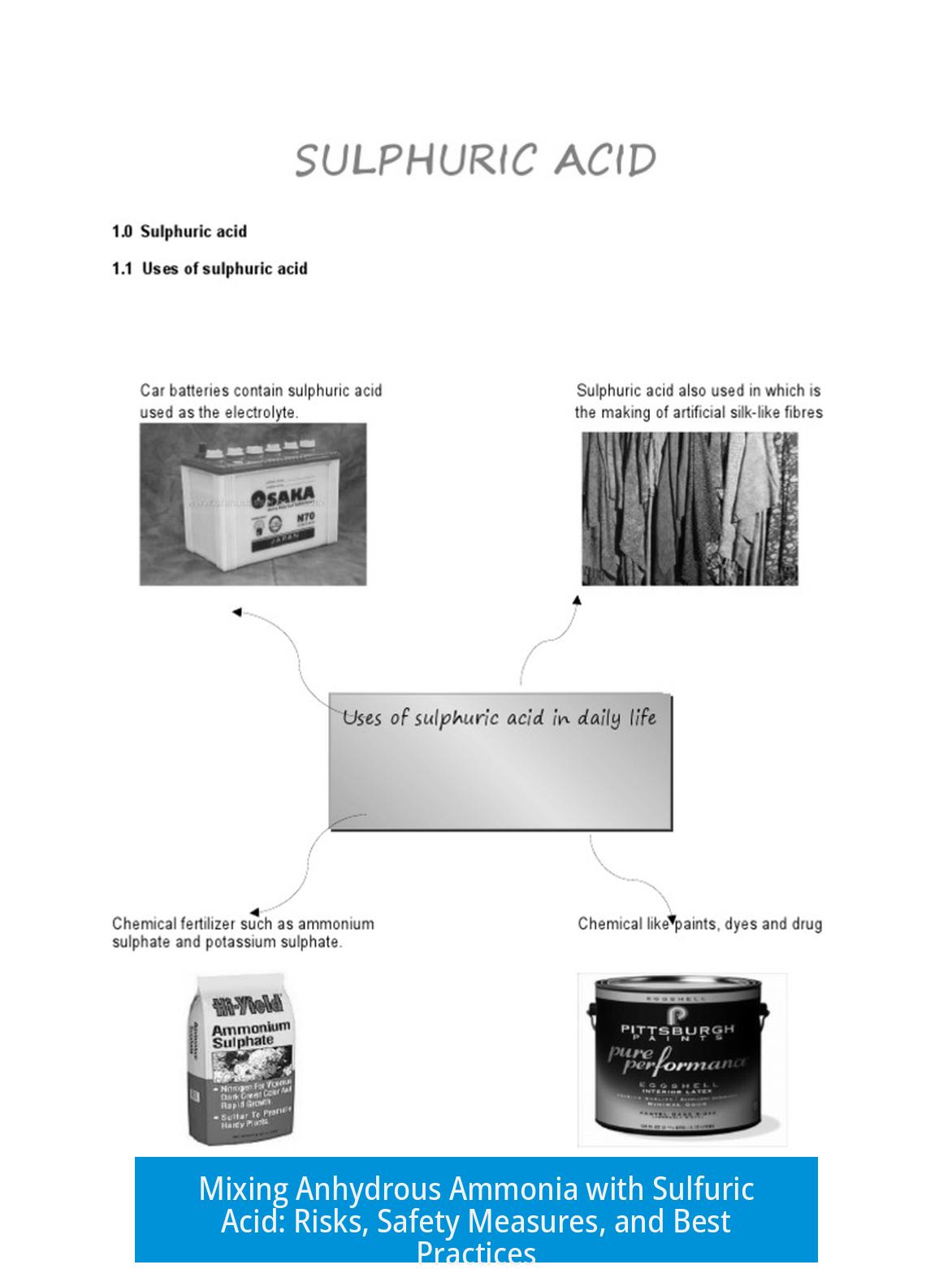

Mixing Anhydrous Ammonia with Sulfuric Acid: Process and Precautions

The mixing of anhydrous ammonia with sulfuric acid is a highly exothermic chemical reaction that produces ammonium sulfate, a common fertilizer. However, the process involves significant safety risks, including heat generation, toxic fumes, and pressure buildup, requiring expert handling and strict safety measures.

Chemical Reaction and Product Formation

The reaction between sulfuric acid (H2SO4) and anhydrous ammonia (NH3) forms ammonium sulfate ((NH4)2SO4), a solid salt widely used in agriculture. The balanced chemical equation is:

NH3 + H2SO4 → (NH4)2SO4

The stoichiometry shows that 34.06 grams of anhydrous ammonia require exactly 108.11 grams of 97% w/w sulfuric acid for complete neutralization. For example, neutralizing 20 gallons of liquid ammonia (~51.6 kg) needs approximately 163.8 kg of concentrated sulfuric acid.

Key Hazards and Reaction Characteristics

- Exothermicity: The neutralization releases a large amount of heat rapidly, which can cause boiling and vessel rupture if uncontrolled.

- Vapor and Fume Risks: Ammonia’s boiling point is -28°F, so it readily vaporizes at ambient temperatures, producing toxic fumes difficult to contain even with ventilation systems.

- Pressure Build-up: Boiling and gas formation increase internal pressure in storage containers, risking structural failure without venting.

- Aquatic Toxicity: Both ammonia and ammonium sulfate pose hazards to aquatic environments.

Recommended Safety Procedures

Due to the hazards, untrained personnel should not attempt this reaction. Expert supervision and specialized personal protective equipment (PPE) are essential. Suitable PPE includes:

- Full face respirators

- Chemically resistant gloves

- Hazmat suits such as PVC or at least thick overalls

To minimize risk, ammonia must be diluted with large volumes of water cooled with ice prior to acid addition. Experts recommend at least five gallons of water per gallon of anhydrous ammonia. Acid addition must be very gradual, with continuous temperature monitoring, ice replenishment, and regular pH checks using blue litmus paper until it turns red, signaling safe ammonium sulfate formation.

Technical Controls for Neutralization

Automated systems with pH probes and acid dosing pumps are standard for aqueous ammonia neutralization. These systems aim for a target pH of 3-5 initially, adjusting dosing rates accordingly. Manual slug dosing is too risky due to rapid heat release and gas evolution.

Handling, Storage, and Disposal Considerations

Anhydrous ammonia requires storage at cryogenic temperatures to remain liquid. Most common chemical totes are not rated for ammonia’s vapor pressure, especially above 10% concentration, increasing risk of container rupture or leaks during transport. Proper venting and pressure management are critical.

Waste generated from this neutralization is regulated, and facilities must often hold EPA licenses to conduct onsite treatment legally. Transporters require special certifications and respiratory protection for loading and unloading.

Given these constraints, it is generally safer and more efficient to sell or transfer anhydrous ammonia to licensed chemical waste management companies or fertilizer producers. Dilution with water reduces hazard volume, but ultimate disposal must comply with hazardous waste regulations.

Alternative Approaches and Recommendations

- Consult local fertilizer dealers for handling advice or potential reuse pathways.

- Do not attempt neutralization without expert supervision due to explosion, heat, and vapor risks.

- Recycle ammonia by storing in appropriate pressure-rated containers and repair faulty equipment if possible.

- Ammonium hydroxide and ammonium phosphate can be valuable byproducts, but require specialized processing.

Summary of Best Practices

| Aspect | Recommendation |

|---|---|

| Mixing | Never mix directly without dilution; always cool and add acid slowly |

| PPE | Use full respiratory protection and chemical resistant clothing |

| Containment | Use vented, pressure-rated vessels stored below ammonia boiling point |

| Disposal | Hire licensed chemical waste companies for neutralization and disposal |

| Environmental | Avoid release of ammonia or ammonium sulfate into waterways |

Key Takeaways

- Mixing anhydrous ammonia and sulfuric acid is highly exothermic and produces toxic vapors.

- The product ammonium sulfate is a common fertilizer but requires careful controlled synthesis.

- Professional handling, dilution, cooling, and PPE are mandatory to prevent accidents.

- Onsite neutralization often demands legal licensing and use of specialized equipment.

- Disposal or resale through certified waste management companies is strongly advised over DIY attempts.

What safety precautions are essential when mixing anhydrous ammonia with sulfuric acid?

Use full face respirators, chemically resistant gloves, and protective suits like PVC hazmat gear. Perform the process with an experienced chemist present under strict ventilation.

Why is temperature control critical during the neutralization?

The reaction is strongly exothermic and can cause rapid boiling. Keeping the mixture cold with ice and water prevents dangerous vapor pressure and ammonia gas release.

How should sulfuric acid be added to anhydrous ammonia for neutralization?

Add acid slowly and in small amounts while continuously checking pH levels. Maintain temperatures near freezing and add more ice as needed to absorb heat.

What happens chemically when anhydrous ammonia reacts with sulfuric acid?

They form ammonium sulfate, a common fertilizer. Once the pH turns acidic, indicated by red litmus paper, the product is safe to store at room temperature.

What legal and disposal considerations exist when handling this mixture?

Facilities need EPA licenses for waste treatment. Use certified transporters and follow special handling rules as ammonia vapors pose respiratory hazards.

Leave a Comment