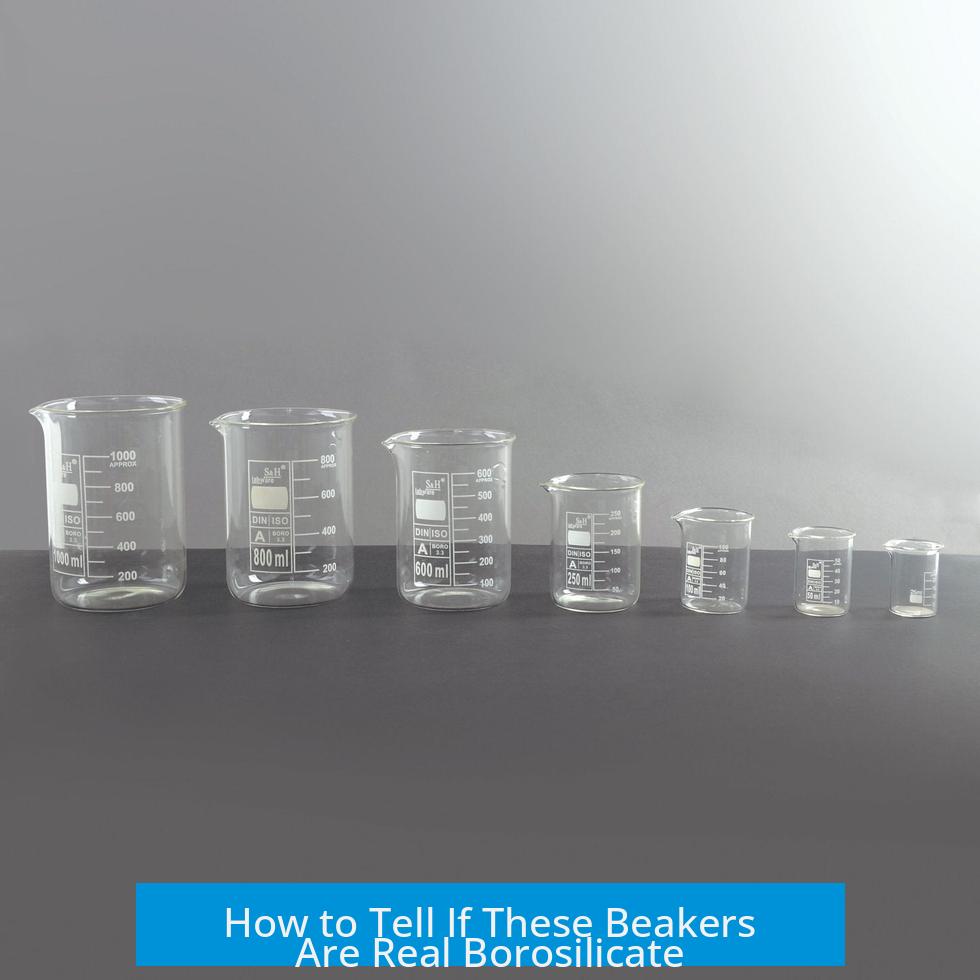

How to Tell If These Beakers Are Real Borosilicate

Determining if beakers are genuine borosilicate involves tests for heat resistance, visual inspection, mechanical behavior evaluation, and sometimes advanced analysis. The key is to confirm their ability to withstand thermal shock and verify their physical properties.

Heat Resistance Tests

Borosilicate glass is known for its low thermal expansion and high heat resistance. Testing this property offers quick clues about authenticity.

- Boiling Water to Ice Bath Test: Heat water to boiling inside the beaker, then immediately place the hot beaker into an ice bath. Genuine borosilicate generally withstands this shock without cracking due to minimal thermal expansion. If the beaker cracks, it is likely soda-lime glass or a low-quality product.

- Freezer to Boiling Water Test: Cool the beaker in a freezer for about an hour, then pour boiling water directly into it. Borosilicate glass remains intact during this rapid temperature change, whereas soda-lime glass frequently breaks.

- Direct Flame Exposure: Applying a direct flame to one end of the beaker helps evaluate its melting point. Borosilicate glass resists melting or deformation under a flame that would damage soda-lime glass. Observing how heat transfers through the beaker can also differentiate types.

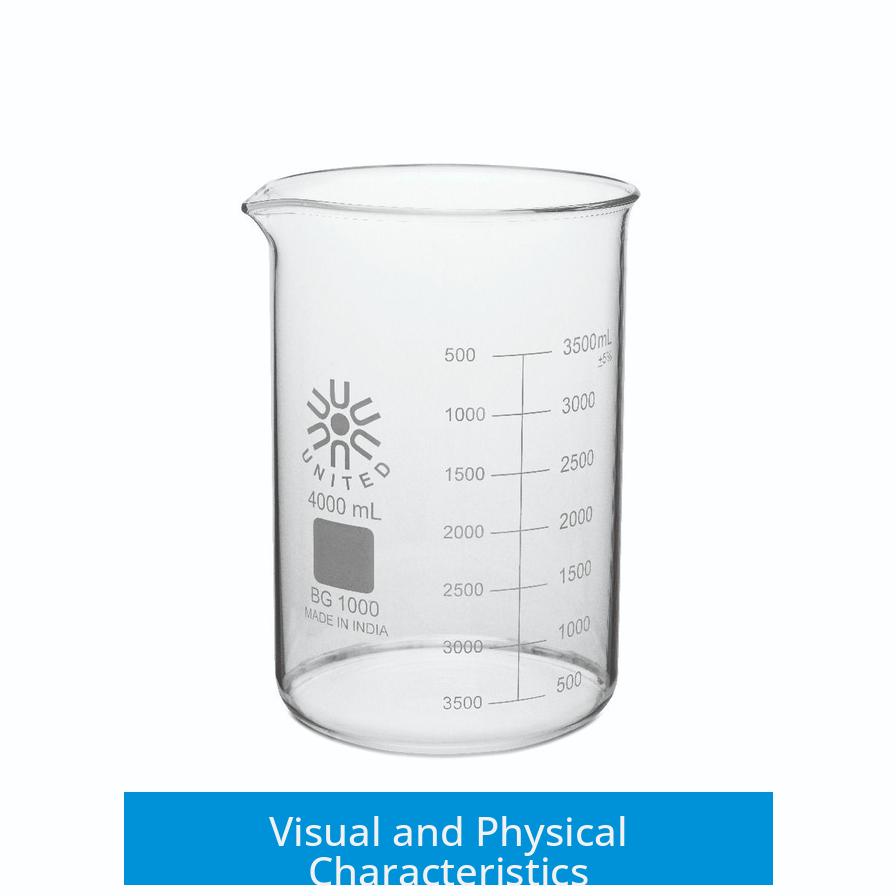

Visual and Physical Characteristics

A careful visual inspection offers preliminary clues regarding the type of glass.

- Color Inspection: Borosilicate glass typically has a very faint greenish or clear tint. If the beaker shows a strong green or teal color, it is probably soda-lime glass, which contains more iron impurities. The edges can be examined—the green edge often indicates soda-lime glass.

- Weight and Density: Borosilicate glass has a density around 2.23 g/cm3, while soda-lime glass is denser, about 2.5 g/cm3. Using an Archimedes setup (weighing in air and submerged in water), one can deduce glass density and hint at its type.

Mechanical and Thermal Behavior Tests

Annealing quality and thermal expansion evaluation can shed light on the beaker’s durability and authenticity.

- Annealing and Stress Analysis: Viewing the glass under a polariscope reveals internal stresses. Properly annealed borosilicate exhibits even stress distribution. Internal stress lines indicate poor manufacturing or soda-lime glass, which can break easily under thermal stress.

- Thermal Expansion Measurement: Measuring the diameter of the beaker before and after heating with precise tools like digital calipers can show expansion. Borosilicate has a low thermal expansion coefficient (~3.3×10−6/°C), much less than soda-lime glass (~9×10−6/°C).

Additional Methods and Indicators

- Mineral Oil Test: When submerged in mineral oil, borosilicate glass often becomes less visible due to matching refractive indices.

- Texture and Taste: Some users note borosilicate feels “crunchy” or “fizzy” on the edges, although this is subjective and least reliable.

- XRD Analysis: For absolute confirmation, grinding a fragment and conducting X-ray diffraction analysis reveals the material’s composition but requires lab equipment.

Warnings and Recommendations

- Glass type alone doesn’t ensure durability. Low-quality borosilicate may crack under thermal stress.

- Avoid very cheap or unbranded sources, especially from unreliable vendors.

- Chinese glassware often matches advertised specifications, but vigilance remains essential.

- Users report safer experience when monitoring heating processes slowly rather than applying rapid temperature changes.

User Experience Insights

Some users successfully distill high-temperature substances using beakers bought online, suggesting their glass is borosilicate. However, they also exercise caution due to potential breakage.

Others observe color cues and conduct simple boiling and cooling tests, trusting only those beakers that survive multiple heat cycles without damage.

| Test Method | Indicator of Borosilicate | Notes |

|---|---|---|

| Boiling to Ice Bath | No cracks, intact | Quick and effective for thermal shock resistance |

| Freezer then Boiling Water | Withstands sudden temperature rise | Simulates extreme lab conditions |

| Visual Color | Clear to faint green tint | Strong green hints soda-lime |

| Density Measurement | ~2.23 g/cm3 | Requires scales and water displacement method |

| Polariscope Stress Test | Even annealing, no stress lines | Advanced but reliable |

| Direct Flame Test | Does not melt/deform easily | Simple lab flame exposure |

Key Takeaways

- Borosilicate glass withstands rapid temperature changes without cracking.

- Visual signs like color and density help differentiate borosilicate from soda-lime glass.

- Internal stress testing and thermal expansion measurements improve reliability.

- Cheap glassware may be falsely labeled; perform multiple tests before trust.

- Combining heat resistance tests with visual inspection provides the best practical verification.

How to Tell If These Beakers Are Real Borosilicate?

If you want to know whether your beakers are truly borosilicate, the best straightforward way is to put them through simple heat shock tests and color inspection—if they survive sudden temperature swings without cracking and look clear or bluish rather than greenish, you probably got genuine borosilicate glass. But hang on, that’s just the start of the journey! Let’s dive into the nitty-gritty details, actionable tests, and tips to help you separate the science-grade heroes from the soda lime impostors.

So, you’ve got a lab full of beakers, maybe from a mysterious online vendor, or inherited from a generous chemist friend. How do you make sure these babies don’t shatter when you’re boiling acids or cooling hot solutions? Let’s cook up some practical tests.

Heat Resistance Tests—Your First Line of Defense

Borosilicate is known for its impressive thermal shock resistance. So if your glass can handle abrupt temperature changes without drama, you’re on the right track.

Try this: Boil water in the beaker and then plunge it into an ice bath or pop it in the fridge. If the beaker cracks, that’s sad news—likely soda lime glass or low-quality—throw it out or reserve it for less adventurous tasks. But if the beaker emerges unscathed, congratulations! You probably have boro 3.3, the most common form of borosilicate glass (yes, there’s a sciencey version number). This test isn’t bulletproof but reliable enough for most practical purposes.

Another cool trick: Freeze your beaker solid for an hour, then pour boiling water inside. If it doesn’t crack or explode, that’s some robust glasswork! No need to risk a fridge meltdown here—place the beaker on a tray to catch any messes just in case.

One brave tester even went a step further—took the beaker from boiling hot water straight into a salty ice bath. No cracks, no pops. Score one for the cold, salty borosilicate! Worth noting though: always handle with care—no need to tempt fate.

Visual and Physical Clues—Don’t Judge a Beaker by Its Color?

You can tell quite a bit just by looking. Genuine borosilicate tends to be clear or faintly bluish, while soda lime glass often has a more pronounced green or teal tint—especially visible at the edges.

Here’s a fun trick: Check the edges of the beaker. A green tint? Probably soda lime glass. Bluish or crystal clear? You’re looking at real borosilicate, or at least something close enough.

Weight can help too, if you have the equipment. Borosilicate is lighter at about 2.23g/cc, while soda lime clocks in around 2.5g/cc. Use Archimedes’ principle and a little patience if you want to bring out your inner scientist.

Mechanical and Thermal Behavior Tests—Digging Deeper

Wondering about internal stresses lurking under the surface? A polariscope reveals these invisible fractures. Properly annealed borosilicate will show even stress, while poorly made glass might have weak spots that threaten to break on a whim—a fatal flaw if you’re boiling expensive solutions for days like one user who guarded their setup during a €7,000 experiment.

Want to geek out? Measure the beaker’s diameter with a digital caliper before and after boiling water. Borosilicate expands less under heat, so you should see minimal differences. It’s like the glass version of “keep calm and carry on.”

Or, grab a Bunsen burner. Hold one end of the beaker and flame the other. If the heat spreads evenly and doesn’t cause the glass to warp quickly, that’s a mark for borosilicate. Soda lime glass heats unevenly and melts easier under direct flame. Remember, borosilicate is easier to shape and less stubborn when heated; soda lime complains loudly.

Advanced Methods—When You Want to Go All Sherlock

If you’re really serious, buy two pieces of your beaker. Grind one into powder and send it to an X-ray Diffraction (XRD) analysis. This will reveal the exact crystal structure and confirm if it’s borosilicate or not. Bit overkill for home use, but hey, we love science!

Here’s a quirky test: submerge your beaker in mineral oil. Borosilicate glass nearly disappears due to refractive index matching, making it look almost invisible in the oily bath. It’s the glass Houdini trick—very satisfying to watch.

One unexpected claim is about taste and texture—borosilicate glass supposedly tastes “crunchy” or fizzy, though we recommend sticking to the visual and heat tests rather than licking labware. Safety first!

Warnings & Recommendations—Buying Smart Matters

Buying cheap beakers is tempting but risky. A glass can be “borosilicate” by name but still be low quality, full of stress points, or poorly annealed. Don’t skimp on your labware—invest in decent brands or trustworthy sources.

Warning: AliExpress often sells glassware labeled “borosilicate” that’s actually junk. However, some Chinese manufacturers produce excellent genuine borosilicate glass too. If they claim borosilicate, chances are good, but verify with the tests above.

Real User Stories—Worth Listening To

Some users swear by the thermal shock tests and keep their labs running safely for years. One user described distilling concentrated sulfuric acid multiple times at 337°C using Chinese Amazon glassware without failure—impressive, though not for the faint-hearted!

Others confess to babysitting their beakers, heating slowly for days just to avoid accidents. Overkill? Maybe, but paying for peace of mind is priceless when costly chemicals are involved.

Summary Table of Key Tests and Indicators

| Test/Indicator | How to Perform | Expected Borosilicate Result |

|---|---|---|

| Heat Shock | Boil water, then ice bath or freeze, then boiling water | Survives without cracking |

| Color Inspection | Observe edges and body color | Clear or bluish, not greenish |

| Polariscope Stress Test | Look for even annealing | Minimal or no internal stress lines |

| Flame Resistance | Apply Bunsen burner heat to one end | Glass resists melting, spreads heat evenly |

| Density Test | Measure volume and mass, calculate density | About 2.23 g/cc |

| Mineral Oil Submersion | Submerge beaker in mineral oil | Beaker nearly disappears |

Final Thoughts

Determining if a beaker is real borosilicate isn’t complicated—but it does require care and a bit of cleverness. Start with safe, non-destructive heat shock tests and keep an eye on color. If you’re working with valuable or hazardous materials, stepping up to stress analysis or flame tests can save you from heartbreak and potential lab disasters.

Remember, quality matters just as much as type. Don’t fall for “borosilicate” impostors from dubious sellers. Trust your senses, run the tests, and upgrade your glassware investment if needed. Your experiments (and your nerves) will thank you.

Ready to test your beakers? Who else has faced the dreaded moment of “Will it crack or won’t it?” Share your stories and tricks! Sometimes the best way to learn is hearing how others tamed their glassware beasts.

How can I test if a beaker is real borosilicate using temperature changes?

Boil water in the beaker, then place it in an ice bath. If it cracks, it’s not borosilicate. Real borosilicate tolerates rapid temperature shifts without breaking.

What visual signs indicate a beaker might not be borosilicate glass?

Check the color around the edges. A green tint usually means soda-lime glass. True borosilicate often has little to no green and may appear clearer or have a bluish edge.

Is there a simple test involving freezing and boiling to verify borosilicate?

Yes. Freeze the beaker for about an hour, then pour boiling water inside. If it survives without cracking, it likely is borosilicate.

Can using a polariscope help identify real borosilicate beakers?

Yes. Polariscope viewing reveals internal stresses. Properly annealed borosilicate has even stress distribution, while uneven stresses indicate poor quality glass.

Does weight or density help to distinguish borosilicate from other glass types?

Density differs slightly: borosilicate is around 2.23 g/cc, soda-lime about 2.5 g/cc. Measuring weight versus volume can help if you have accurate tools.

Leave a Comment