Tried to Clean Silver Using the Power of Chemistry, and It Made It Worse?

Cleaning silver with chemistry can sometimes worsen the problem due to impurities in the metal, contaminants on the jewelry, or incorrect application of the chemical cleaning method. This article explores why chemical silver cleaning may fail and how to avoid common mistakes. It also provides guidance on alternative polishing techniques to restore silver’s shine effectively.

Why Does Chemical Cleaning Make Silver Worse?

When silver appears more tarnished after cleaning attempts, the issue often lies in the composition of the item or how the cleaning process was performed. The following factors commonly cause cleaning failures:

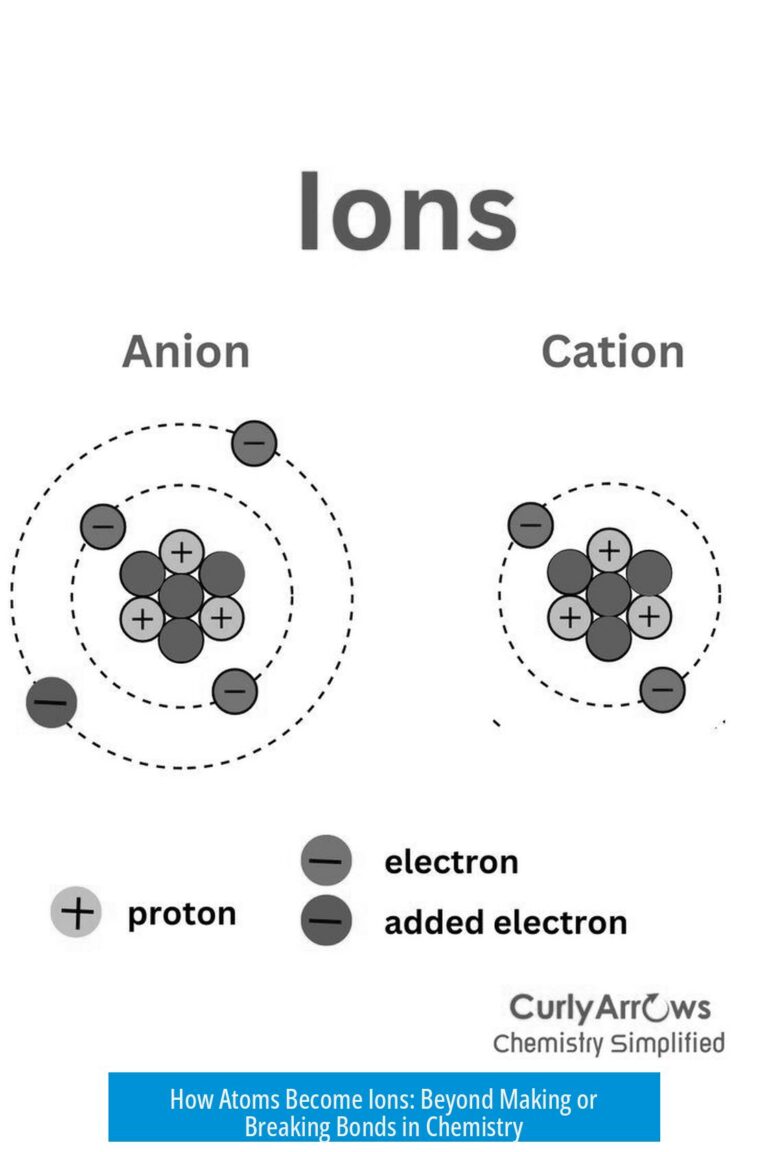

- Metal Impurities: Some jewelry contains alloys such as nickel or copper rather than pure sterling silver. These metals react differently and may darken rather than clean during chemical treatments.

- Surface Contaminants: Body oils, dirt, or residual chemicals on jewelry can interfere with cleaning reactions. Not pre-washing these contaminants often results in incomplete or worsened tarnishing.

- Incorrect Cleaning Application: Certain chemical methods require specific setups. Wrapping silver in aluminum foil rather than lining a container with foil and submerging in the cleaning solution can trap tarnish and cause blackening.

Understanding the Chemistry Behind the Aluminum Foil and Baking Soda Method

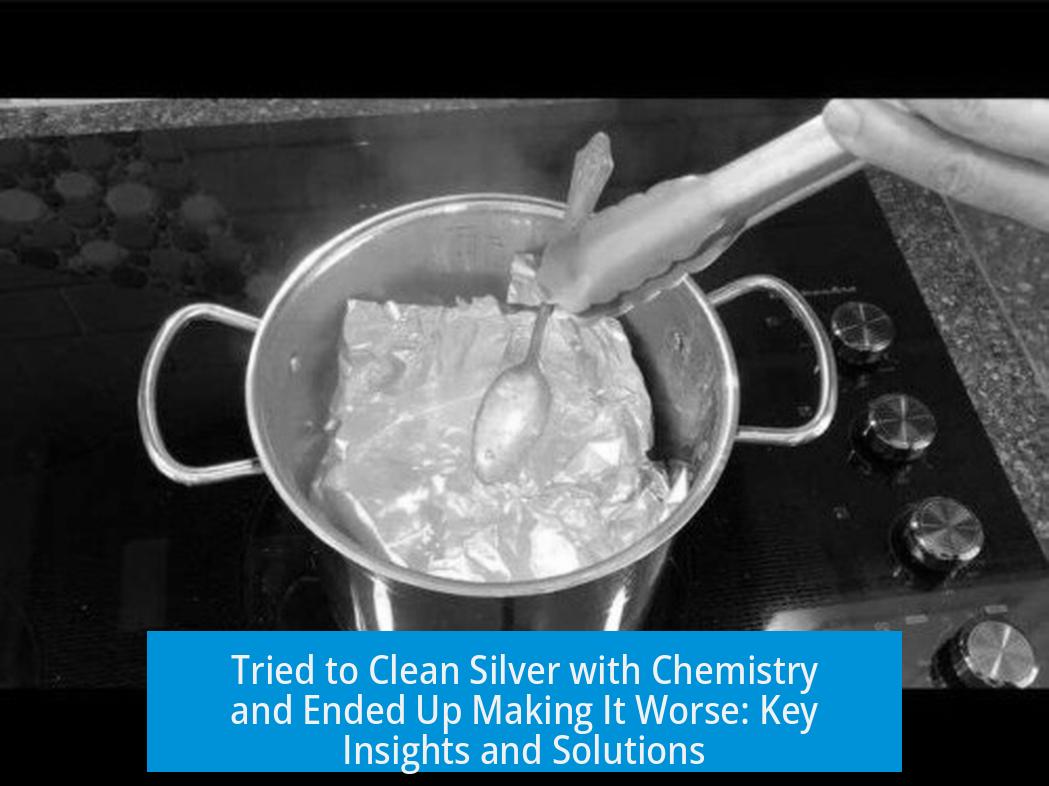

This popular silver cleaning technique uses a redox reaction that transfers tarnish from silver to aluminum foil. It involves submerging silver in a solution of hot water and baking soda, placed inside an aluminum foil-lined pan.

| Step | Purpose | Key Detail |

|---|---|---|

| Line pan with aluminum foil | Provide a sacrificial metal surface to capture tarnish | Foil must be exposed and not wrapped around silver |

| Prepare hot water and baking soda solution | Facilitates redox reaction | Baking soda provides alkaline environment |

| Place silver item in pan | Allow electron transfer from tarnish to foil | Silver should not be wrapped in foil |

| Pour solution over foil and silver | Enable cleaning reaction | Solution must cover silver and foil adequately |

When successful, the tarnish (silver sulfide) transfers to the aluminum foil surface, which may show browning. The silver item emerges clean and shiny. The distinctive sulfur smell during the process confirms the chemical reaction.

Why Wrapping Silver in Foil Worsens Tarnish

Wrapping silver in aluminum foil traps the tarnish inside the packet, preventing it from transferring onto the foil surface where it belongs. Additionally, sealing the silver inside a foil package in solution can cause uneven reactions and promote darkening due to copper or nickel alloys in the item. This may increase the visible tarnish or create black spots.

Experts recommend lining the container with foil and placing silver items directly on or near it, not wrapping them. The foil acts as an electron sink, and exposure during the reaction is critical to success.

Contaminants and Pre-Cleaning Preparation

Natural skin oils, lotions, or previous residues on silver inhibit proper chemical cleaning. It is essential to wash silver items thoroughly with detergent and rinse them clean before immersion in the baking soda and aluminum foil solution.

This step ensures no surface contaminants block electron flow or interfere with the chemical reaction, increasing the chance of restoring shine.

Alternative or Complementary Silver Cleaning Approaches

If the chemical method alone is ineffective or causes discoloration, consider the following complementary techniques:

- Commercial Silver Polishing Creams: These products use mild abrasives and chemicals designed for silver to gently remove tarnish and restore luster.

- Combination Cleaning: Applying silver polish before using the baking soda method can ease polishing afterward. Equal parts baking soda and silver polish sometimes improve results.

- Polishing Cloths: After electrochemical cleaning, some silver items may show spots or beads of discoloration. Polishing them with a dedicated silver cloth restores a smooth, shiny surface.

Recognizing Successful Cleaning Reactions

During a successful electrochemical clean, the following signs appear:

- Sulfur odor from reduction of silver sulfide tarnish

- Browning or discoloration on aluminum foil where tarnish deposits

- Visible transfer of tarnish residue from silver to foil

Absence of these can indicate process failure or improper execution.

Summary of Best Practices in Chemical Silver Cleaning

- Know the metal composition; avoid cleaning alloys that include copper or nickel as silver.

- Pre-wash silver thoroughly to remove body oils and contaminants.

- Line the cleaning container with aluminum foil; do not wrap silver items.

- Use hot water and baking soda solution; ensure complete coverage of silver and foil.

- Look for chemical reaction indicators: sulfur smell and foil discoloration.

- Follow chemical cleaning with polishing using a silver cloth or commercial polish if necessary.

Key Takeaways

- Metal impurities like copper and nickel can cause silver cleaning to fail or worsen.

- Contaminants on silver prevent chemical reactions needed to remove tarnish.

- The aluminum foil and baking soda method requires correct setup: foil lining, no wrapping.

- Polishing creams and cloths complement chemical cleaning for best results.

- Identifying signs of reaction helps confirm the cleaning process is working.

Leave a Comment