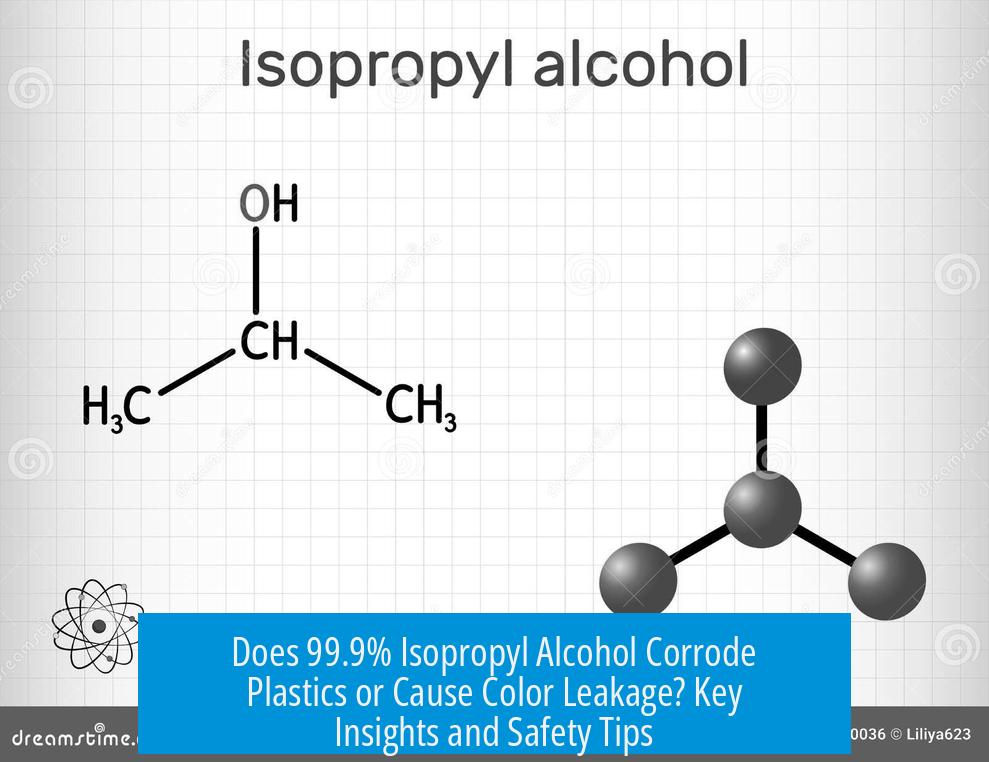

Does 99.9% Isopropyl Alcohol Cause Corrosion or Colour Leakage to Plastics?

99.9% isopropyl alcohol can cause corrosion and color leakage in certain plastics, but the effect depends strongly on the plastic type and exposure duration. It does not universally damage all plastics on contact, but higher concentrations increase the risk of degradation over time.

Impact on Different Plastics

Isopropyl alcohol at 99.9% is a powerful solvent. It affects plastics differently.

- Some plastics are resistant and show no immediate damage.

- Others may swell, crack, or leach colorants after prolonged exposure.

- Plastics such as polypropylene may degrade with strong chemicals but can resist isopropanol better.

Since 90% to 91% concentrations already damage some plastics, 99.9% is more potent and thus more likely to cause corrosion.

Time Dependency and Exposure

Damage seldom occurs instantly. Corrosion or color bleeding typically happens over time, especially with continuous contact.

Short, incidental exposure usually does not harm plastics, but repeated or extended contact increases risks.

Identifying Plastic Compatibility

Knowing the plastic type is key.

- Manufacturers often mark plastics with recycling codes or acronyms, such as PET, HDPE, or PVC.

- Chemical resistance charts provide valuable guides to which plastics withstand isopropanol.

Consulting these charts before use ensures compatibility and prevents damage.

Practical Context

Many 99.9% isopropyl alcohol bottles come in plastic containers without immediate damage, indicating some plastics resist this concentration well.

Users should consider the specific plastic and application when handling or storing high-purity isopropanol. For example, improper cleaning agents can irreversibly harm sensitive plastic components, as seen with bleach on polypropylene filters.

Summary of Key Points

- 99.9% isopropyl alcohol can corrode or cause color leakage, varying by plastic type.

- Damage usually requires extended contact, not instant exposure.

- Identifying plastic type and consulting chemical resistance charts prevents unintended harm.

- Some plastics safely contain high-purity isopropanol, as commonly observed in commercial packaging.

- Caution is advised when applying solvents to plastic parts in any cleaning or industrial process.

Does 99.9% Isopropyl Alcohol Cause Any Corrosion or Colour Leakage to Plastics?

If you’ve ever wondered whether 99.9% isopropyl alcohol can harm your prized plastic gear, you’re not alone. The straight answer is yes, it can cause corrosion or color leakage in some plastics, but this really depends on the type of plastic and exposure time. Not all plastics are made equal, and isopropyl alcohol’s mischievous tendencies vary quite a bit. Let’s untangle the mystery with some facts and practical advice.

First off, it’s crucial to note the concentration. At 90–91%, isopropyl alcohol already has a reputation for damaging certain plastics. So, with a ruthless purity of 99.9%, expect it to pack a punch.

How Does Isopropyl Alcohol Affect Plastics?

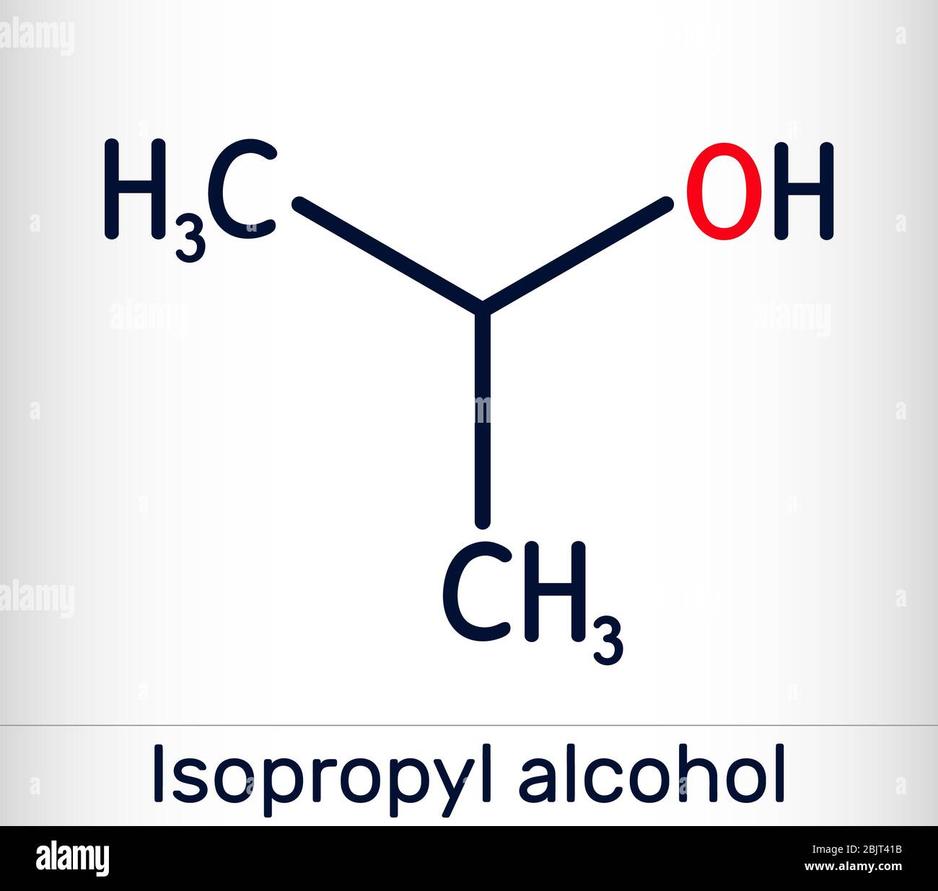

Isopropyl alcohol (C3H8O for the chemistry buffs) doesn’t corrode every type of plastic. That said, some plastics are vulnerable to this high-concentration solvent. And the damage doesn’t usually show up right away. You might dunk a plastic part into 99.9% iso and see no immediate effect, but leave it soaking or exposed over days or weeks? That’s when micro-cracks, clouding, warping, or even color leakage may show their unwelcome faces.

Take this real-life tidbit: the writer owns a bottle of 99.9% isopropyl alcohol stored in plastic. If 99.9% iso immediately destroyed all plastics, that wouldn’t be possible. This proves that certain plastics are indeed resistant to it—but which ones exactly?

Plastic Type Is the Game Changer

Identifying your plastic type is the golden rule. Most modern plastic items carry a tiny stamp or imprint revealing their type, such as PETE, HDPE, PVC, PP, or others. Once you know the plastic type, consulting a chemical resistance chart can save your gear—and nerves.

| Plastic Type | Resistance to 99.9% Isopropyl Alcohol | Notes |

|---|---|---|

| Polypropylene (PP) | High Resistance | Commonly stable. Used in medical containers and labware. |

| Polyvinyl Chloride (PVC) | Moderate Resistance | May soften or discolor upon longer exposures. |

| Polystyrene (PS) | Low Resistance | Prone to cracking and crazing. |

| Polycarbonate (PC) | Low Resistance | Can craze and discolor rapidly. |

| Other Plastics | Variable | Consult the chart for specific types. |

This breakdown illustrates why you must identify the plastic type before plunging your hands—or your items—into 99.9% isopropyl alcohol.

Corrosion Versus Color Leakage: What’s the Difference?

Corrosion means the plastic chemically or physically degrades—think crazing, cracking, or brittleness. Color leakage, on the other hand, happens when dyes or pigments dissolve out of the plastic, causing staining or fading. Both are unpleasant surprises.

Remember, plastic doesn’t “corrode” in the traditional metal sense, but the damage caused by harsh chemicals is just as real and irreversible. This happens because the solvent breaks down polymer chains or pigments inside.

Practical Tips for Using 99.9% Isopropyl Alcohol Safely with Plastics

- Check the Plastic Marking: Look for a recyclable number or acronym on your plastic item. Use a chemical resistance chart to verify compatibility before use.

- Test Before Full Use: Dabble a small hidden spot with the alcohol, wait a day or two, and inspect for changes.

- Avoid Prolonged Exposure: Don’t leave plastics soaking or in constant contact with high-concentration isopropyl alcohol.

- Consider Lower Concentrations: 70-91% isopropyl alcohol is safer for many plastics and still effective as a disinfectant or cleaner.

- Store With Caution: If your isopropyl alcohol is stored in plastic, verify that the container’s plastic type is resistant to prevent leaks or container breakdown.

How Does Isopropyl Alcohol Stack Up Against Other Chemicals?

Here’s a cautionary tale: a user was advised to clean a $800 HEPA filter’s polypropylene parts with bleach. Spoiler alert—it didn’t end well. Chlorine bleach destroys polypropylene bonds, wrecking the filter permanently.

This anecdote drives home a key point—chemical compatibility matters. Isopropyl alcohol isn’t a universal plastic destroyer, but neither are other chemicals. Each chemical-plastic combo behaves differently. Your best bet? Do a quick compatibility check rather than guessing.

Some Personal Experience and Final Thoughts

People who work in labs or medical environments often have 99.9% isopropyl alcohol on hand. Most learn relatively quickly about the materials they handle. For instance, plastics made from polyethylene or polypropylene generally shrug off this solvent, while acrylics and polystyrenes turn brittle or cloudy.

So, if you bought your 99.9% isopropyl alcohol at specialty shops or grew your own by drying lower concentrations, you probably understand these nuances already. For the rest of us mortals, it pays to expand your plastic and chemical knowledge.

In summary, 99.9% isopropyl alcohol can cause corrosion or color leakage to plastics, but whether it does depends on the plastic’s type, colorants used, the concentration, and exposure duration. Always check the plastic type and consult chemical resistance information before use. Test on a small area first. And, when in doubt, consider using lower concentrations that achieve your purpose without the risk of damage.

“High purity solvents are like hiring a ninja—they do their job thoroughly but leave a mess if you’re not careful with their targets.”

Now, armed with this knowledge, will you dare to soak that cherished plastic gadget in 99.9% isopropyl alcohol? Or will you opt for a gentler clean? Either way, safety first—your plastics will thank you later.

Does 99.9% isopropyl alcohol cause corrosion to all types of plastics?

No, it depends on the plastic type. Some plastics resist 99.9% isopropyl alcohol, while others can be damaged. Corrosion is not automatic for every plastic.

Can 99.9% isopropyl alcohol cause color leakage from plastics?

Color leakage depends on the plastic and its colorants. Some plastics may leach colorants if exposed for a long time, but this varies widely.

How fast does 99.9% isopropyl alcohol damage plastics?

Damage usually takes time and does not happen immediately. Prolonged exposure increases corrosion risk on vulnerable plastics.

How can I know if my plastic is safe to use with 99.9% isopropyl alcohol?

Check the plastic type stamp on the item. Use a chemical resistance chart to see if that plastic is compatible with isopropyl alcohol.

Is 99.9% isopropyl alcohol commonly sold in plastic containers?

Yes, but usually it is in specific plastic types that resist it. Under normal sale conditions, 91% or 99% solutions are more common.

Leave a Comment