Why Use Solvent Extraction Instead of Just Distilling a Mixture?

Solvent extraction serves important roles that distillation alone cannot fulfill, especially for purifying mixtures and handling compounds unsuitable for distillation.

Limitations of Distillation

- Not all compounds can be distilled safely.

- Some substances decompose at temperatures below their boiling points.

- Many compounds have very high boiling points and will break down if heated enough to distill.

Distillation relies on differences in boiling points but fails when the compound is thermally unstable. Such situations require alternative separation methods.

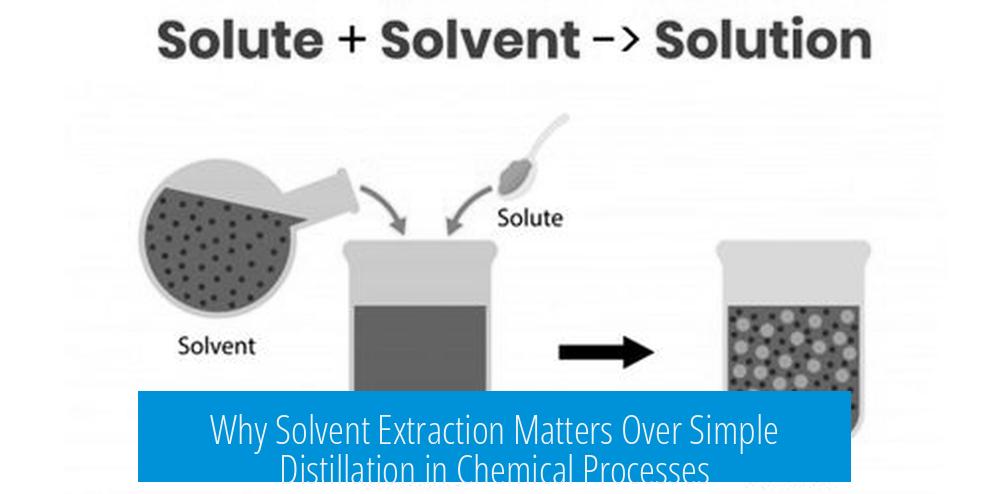

The Purpose of Solvent Extraction

Solvent extraction allows selective transfer of a compound from one liquid phase to another, enabling purification beyond what distillation offers.

Easier Handling with Suitable Solvents

- Switching to solvents with lower boiling points facilitates easier removal later by distillation.

- Choosing solvents with lower toxicity or better compatibility simplifies handling and safety.

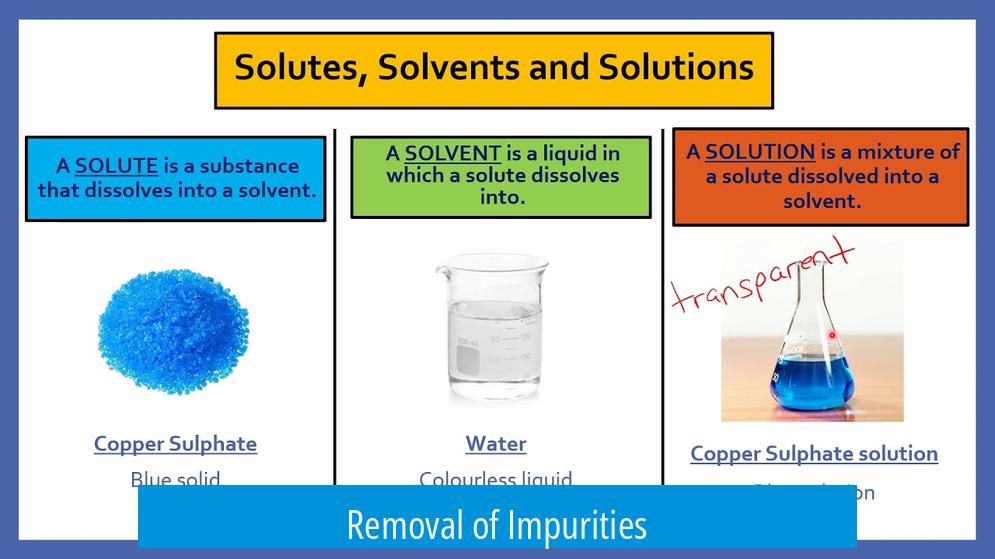

Removal of Impurities

- Extraction removes unwanted byproducts, unreacted reagents, catalysts, and salts.

- These impurities often dissolve preferentially in aqueous or other solvent phases, separating from the product.

Chemical Form Considerations

- Products may exist as salts or ionized forms, which do not separate by distillation.

- Extraction with acidic or basic aqueous solutions converts products into their extractable neutral forms.

Consequences of Skipping Extraction

Omitting solvent extraction to distill a crude mixture may save time but often results in impure products. Distillation alone does not remove non-volatile impurities or chemical forms unsuitable for vaporization.

Summary

| Aspect | Distillation | Solvent Extraction |

|---|---|---|

| Thermal Stability | Requires heat; not suitable for unstable compounds | Operates at mild conditions |

| Impurity Removal | Limited; mainly separates based on boiling points | Effective for removing non-volatile impurities and byproducts |

| Chemical Form | Only volatile neutral forms | Can convert and separate different ionic forms |

| Handling | May involve toxic or high boiling solvents | Choice of solvent tailored for easier handling and safety |

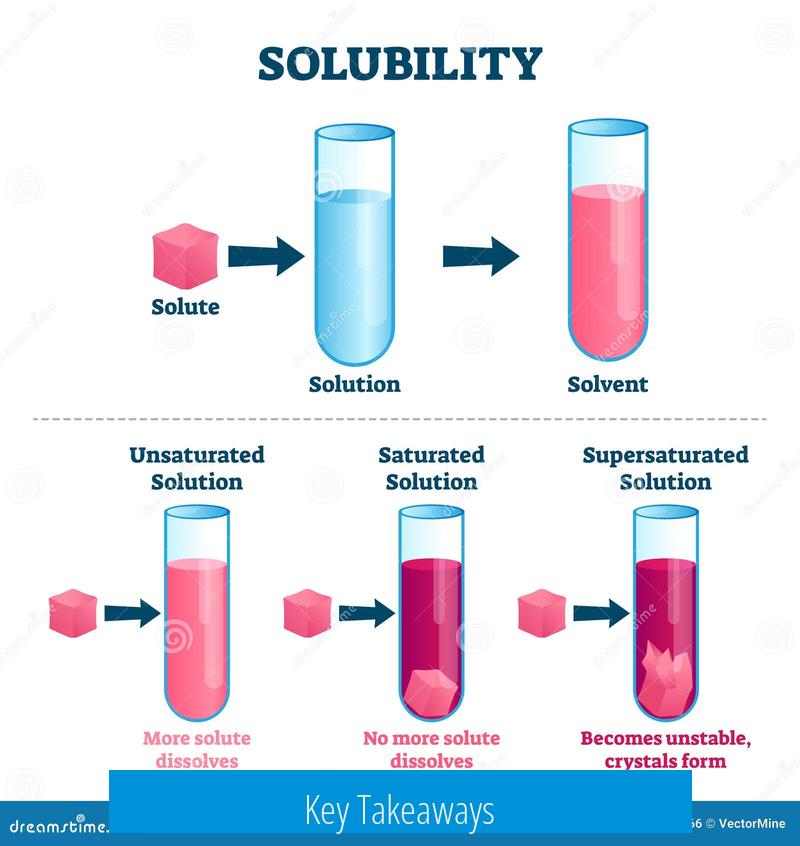

Key Takeaways

- Distillation cannot always safely or effectively separate all mixture components.

- Solvent extraction allows purification by transferring compounds into selected solvents.

- Extraction removes impurities and adapts chemical forms for easier isolation.

- Combining extraction and distillation often yields higher purity products.

What is the Point of Doing Solvent Extraction When We Can Just Distill the Mixture?

Solvent extraction is essential in many chemical processes because distillation alone can’t always do the job. It’s not just about separating — it’s about protecting your product, improving purity, and handling the practical quirks of chemistry. Let’s dive into why solvent extraction often steals the spotlight from distillation, despite distillation’s legendary reputation as a separation champion.

Imagine you have a mixture and you want to isolate a pure compound. On the surface, distillation seems like the go-to method. You heat it up, let the vapor condense, and collect your compound, right? Not always. Sometimes, it’s just not that simple.

Why Distillation Isn’t Always the Answer

First off, not everything can be distilled. Many compounds decompose before their boiling points. Think of it as trying to melt a snowman under a flame that’s just a bit too hot—before it melts, it breaks down into a mess. Some delicate molecules just don’t survive the heat needed for distillation.

Plus, many compounds have insanely high boiling points. Distilling these is like trying to catch a train going cross-country — it’s technically possible but expensive and time-consuming, often leading to product degradation.

So, distillation faces two major hurdles: thermal decomposition and boiling points too high for practical purposes. When these barriers exist, distillation alone doesn’t cut it.

Enter Solvent Extraction: The Unsung Hero

Solvent extraction offers an elegant alternative. Its main goal? To purify the product by “dissolving away” impurities and switching solvents for easier handling. Basically, if your mixture were a messy room, solvent extraction is the methodical cleaning that makes it sparkle before the big showcase — distillation.

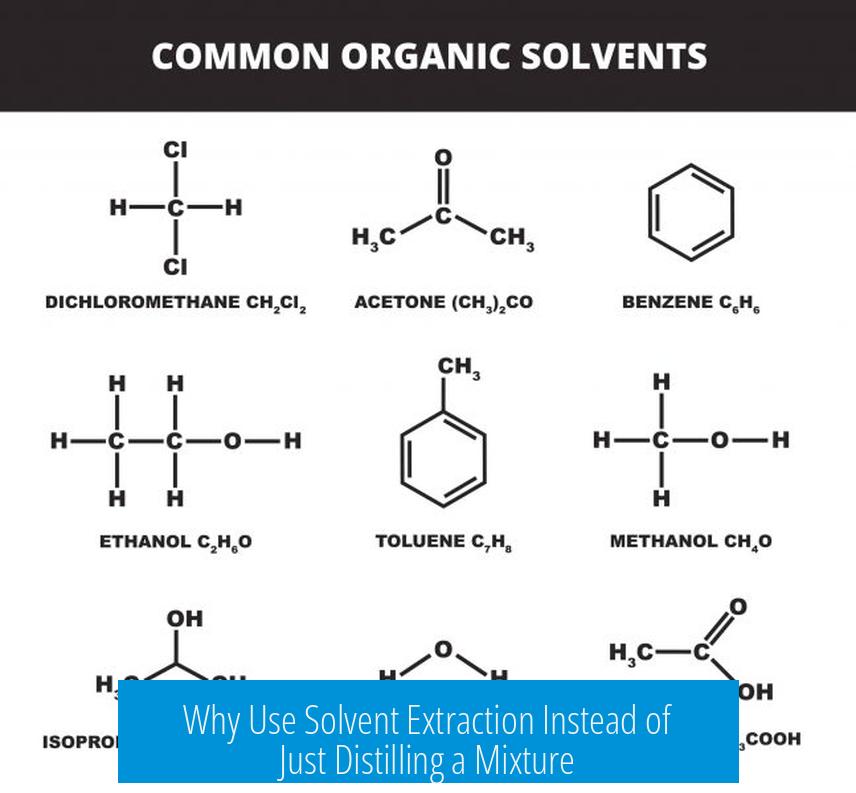

Easier Handling with Suitable Solvents

Your product might be initially dissolved in a solvent that’s hard to deal with — maybe because it has a super high boiling point or it’s toxic. Swapping it with a solvent that’s less scary and evaporates easily makes the next steps much simpler. Imagine trying to clean paint with water instead of some toxic chemical. It’s that straightforward.

Removing Impurities

Raw reaction mixtures often contain byproducts, leftover reagents, catalysts, or salts. These unwanted passengers can ruin your product’s purity. Solvent extraction cleverly removes them by dissolving these impurities into an aqueous phase, leaving your product behind. Think of it as a selective bouncer who keeps the riffraff out.

Chemical Form Considerations

Sometimes, your product refuses to behave nicely—it could be stuck as a salt or in a deprotonated form, making it a nightmare to isolate directly. By tweaking the environment with acids, bases, or salt solutions, solvent extraction changes the product’s behavior so it becomes extractable. This is chemistry’s version of “changing the plan when things get complicated.”

What Happens if You Skip Solvent Extraction? The Hidden Risks

It might be tempting to skip solvent extraction and jump straight to distillation. Sure, it saves time and effort initially. But here’s the catch: your final product could be a messy mix of impurities. It’s like baking a cake without sifting the flour first — you might get a cake, but texture and taste suffer.

In precise chemistry, impurities can affect quality, performance, and safety. For industries like pharmaceuticals, that trade-off is unacceptable.

Distillation Vs. Solvent Extraction: A Practical Comparison

Distillation separates based on volatility differences—ideal for compounds with sufficiently different boiling points and stability. Solvent extraction separates based on solubility differences—perfect when boiling points are too close, or heat damages your product.

“Skipping extraction to distill directly can save time but risks product purity.”

Sometimes solvent extraction serves as the tactical “middle-man,” making your product ready to be distilled cleanly and safely.

A Simple Analogy to Cement the Concept

Ask yourself: What’s the point of division when you can multiply by fractions? It sounds like a riddle, but it makes sense. Sometimes breaking problems into neat, manageable steps is smarter and more efficient than attempting a direct, complicated move.

Solvent extraction is that clever step. It simplifies purification and preserves your product. Distillation, like multiplication, is powerful but sometimes too blunt for the task alone.

Practical Tips for Using Solvent Extraction Effectively

- Identify impurities that are soluble in aqueous phases; choose water or acidic/basic solutions accordingly.

- Choose a solvent with a lower boiling point for easier removal later on.

- Check if your product is in an ionic form that needs conversion to a neutral form before extraction.

- Perform multiple extractions if necessary to maximize impurity removal.

Following these tips can save headaches during your next chemical purification.

Wrapping It Up: The Real Value Behind Solvent Extraction

Solvent extraction isn’t some outdated relic or unnecessary extra labor. It’s a precise, deliberate technique that addresses the physical and chemical realities distillation simply can’t handle alone. By removing impurities, switching to manageable solvents, and modifying chemical forms, solvent extraction ensures your product shines pure and intact.

So next time you wonder: “Why not just distill it?” remember that chemistry isn’t always about the fastest shortcut. It’s about the smartest path to quality.

Do you have an experience where distillation alone led to trouble? Or has solvent extraction saved your project? Drop your thoughts and stories. Let’s discuss how these techniques shape the chemistry world.

Why can’t we always use distillation instead of solvent extraction?

Many compounds break down before boiling, making distillation impossible. Some have very high boiling points, so they decompose rather than vaporize. Extraction allows separation without heating to extreme temperatures.

How does solvent extraction help in purifying a mixture?

Extraction removes impurities like unreacted reagents, catalysts, and salts by dissolving them in a separate solvent. This cleans up the product before further processing like distillation.

Can solvent extraction make distillation easier?

Yes. Extraction can transfer a product into a solvent with a lower boiling point. This reduces distillation temperature and hazards, and helps avoid product decomposition.

Why is chemical form important in solvent extraction?

Products might exist as salts or ionized forms that do not separate well by distillation. Extraction using acid/base or salt solutions converts them to forms suitable for isolation.

What happens if we skip extraction and directly distill?

Skipping extraction saves time but leads to impure products. Impurities can carry over during distillation, reducing yield and quality.

Leave a Comment