What Are Some Cheap Ways to Produce CO2 Gas?

Several affordable methods exist to produce CO2 gas, ranging from simple chemical reactions at home to purchasing CO2 in various forms. The cheapest practical options include buying dry ice or CO2 cylinders, reacting acids with common carbonates like baking soda or limestone, and fermenting sugar with yeast. Each method varies in complexity, cost, and purity of the produced CO2.

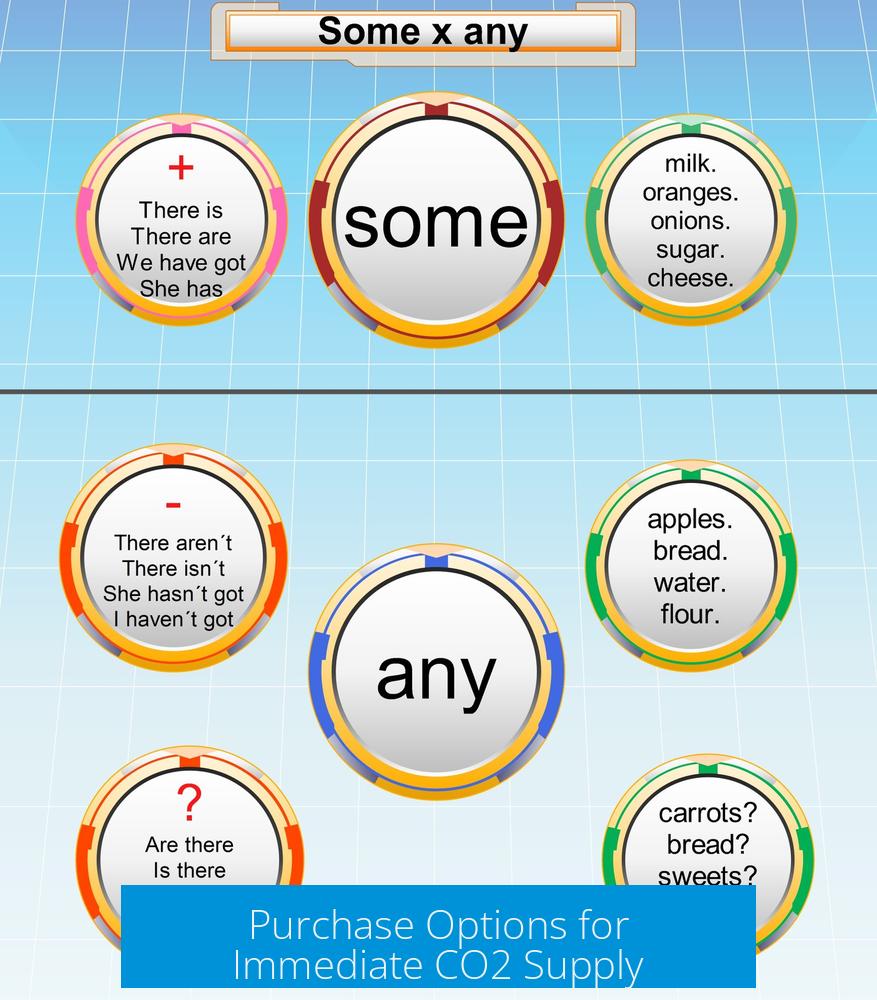

Purchase Options for Immediate CO2 Supply

One straightforward way to obtain CO2 cheaply is to buy it directly. These options provide controlled amounts ready for use.

Dry Ice from Grocery Stores

- Dry ice is solid CO2 readily available at many grocery stores.

- Several pounds can often be purchased for approximately $20.

- This is an immediate source producing CO2 gas as it sublimates.

CO2 Gas Cylinders

- Food-grade CO2 cylinders, commonly used for pressurizing beer kegs, are available at homebrew supply stores or welding suppliers.

- A 5-pound cylinder typically costs between $15 and $20.

- Compressed CO2 cylinders, including SodaStream refills, offer another affordable gas source for about $15 each.

- These require appropriate regulators to control gas flow safely.

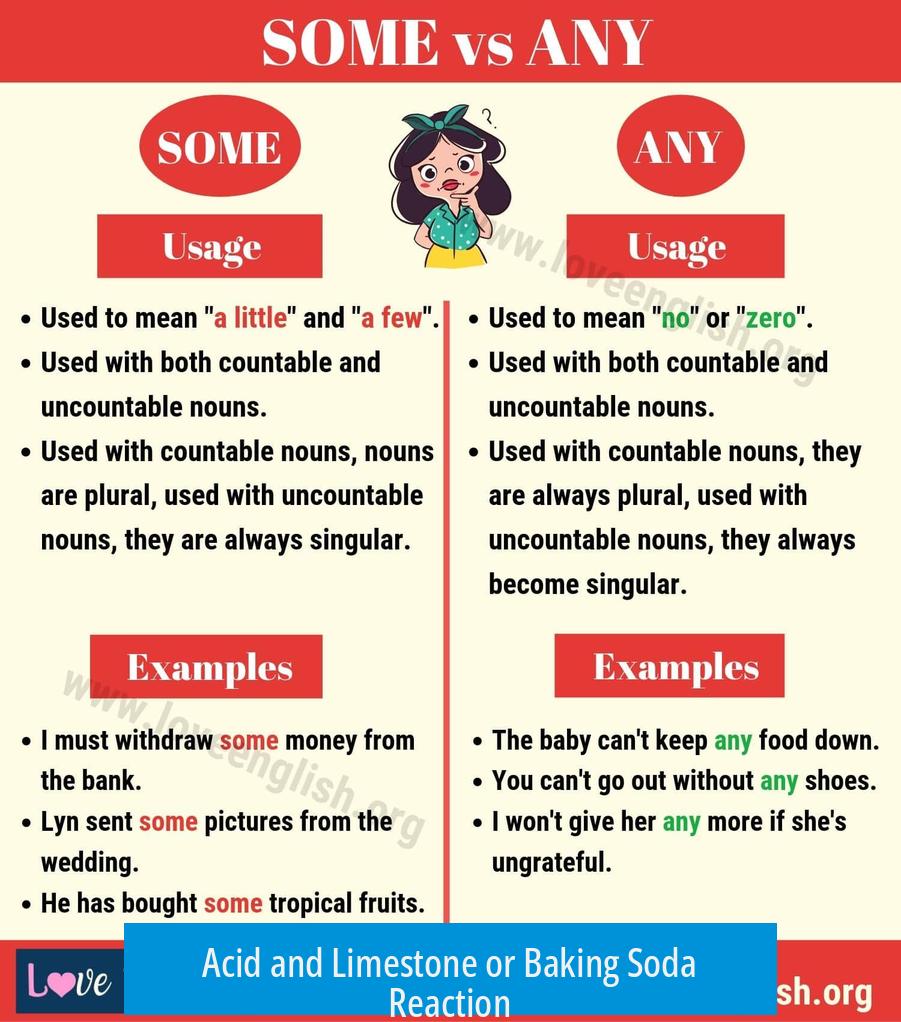

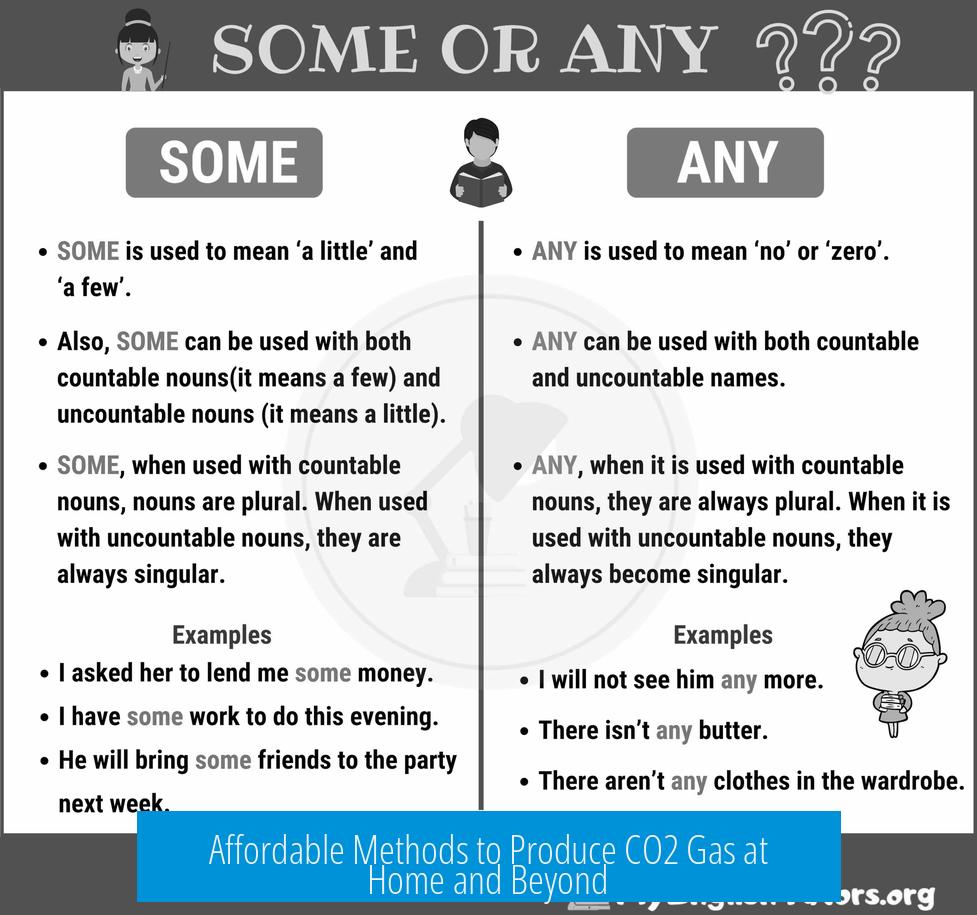

Chemical Reaction Methods to Produce CO2

Chemical generation of CO2 is accessible, inexpensive, and useful for small scale or experimental applications. These reactions generally involve acids reacting with carbonate compounds.

Acid and Limestone or Baking Soda Reaction

- Reacting an acid with calcium carbonate yields CO2 gas.

- Common acids: vinegar (acetic acid) or citric acid.

- Carbonate sources include limestone, eggshells, seashells, or baking soda (sodium bicarbonate).

- Example: pouring vinegar onto baking soda produces bubbling CO2 quickly.

- These ingredients are inexpensive; vinegar and baking soda can be bought cheaply from supermarkets.

Citric Acid and Sodium Bicarbonate Reaction

- This reaction produces CO2 gently and steadily, suitable for aquarium setups or small gas generators.

- An example is an aquarium CO2 generator using 400g of citric acid and sodium bicarbonate each with water.

- The reaction can last days to weeks, producing pressures around 200 psi inside a sealed container.

- Initial investment for the chemicals (~$60 for 10 lbs each) can provide CO2 for a long period.

Thermal Decomposition of Calcium Carbonate

- Heating calcium carbonate (limestone) to about 900°C decomposes it to calcium oxide and CO2.

- This method is energy-intensive and complex for small scale users.

- Suitable primarily for industrial or high-energy setups.

Biological and Fermentation Methods

Biological and fermentation processes generate CO2 naturally and at low cost, though often with impurities.

Sugar Fermentation Using Yeast

- Yeast ferments sugar into ethanol and CO2.

- A 2 kg bag of sugar can produce approximately 295 liters of CO2 over 7–10 days at atmospheric pressure.

- This method supplies slow, continuous CO2, useful for applications like hydroponic gardening.

- CO2 produced contains water vapor and possible flavor compounds; filtration can improve purity.

Biomass Decomposition or Composting

- Decomposition of organic matter via aerobic or anaerobic processes releases CO2.

- Gas mixtures from compost are variable and often contain impurities including methane, sulfur, and nitrogen compounds.

- Scrubbing and purification are needed to extract usable CO2.

- This method is less predictable and may require larger setups.

Biogas and Gas Scrubbing

- Anaerobic digestion produces biogas rich in methane and CO2.

- Biogas requires scrubbing to remove sulfur and other toxins for clean CO2.

- Biogas use is practical in industrial or agricultural facilities with digesters and scrubbing units.

Direct Air and Point Source Capture

Capturing CO2 directly from ambient air or industrial sources is possible but usually not cost-effective for low-volume needs.

Direct Air Capture (DAC)

- DAC technology extracts CO2 directly from the atmosphere.

- Costs are high, roughly $400 per tonne of CO2.

- Generally unsuitable for small or budget-conscious users.

Point Source Gas Capture

- Industrial flue gases from cement, ammonia, or LNG plants contain concentrated CO2.

- Amine scrubbers capture CO2 at approximately $5 per tonne.

- Feasible only at large scale and with industrial access.

Other Considerations and Ideas

Exhaling as a CO2 Source

- Exhaled breath contains CO2 but is extremely dilute and produces minimal gas volume.

- Not practical beyond informal demonstrations or very small-scale purposes.

DIY and Experimental Ideas

- Some seek homemade CO2 generation methods like fermenting organic waste.

- Such methods may work but require careful planning and safety precautions.

Commercial Methanol Production Using CO2

- Some companies use captured CO2 to produce methanol at scale (e.g., 200,000 metric tonnes annually).

- Facilities can be purchased commercially but are costly and complex.

- Relevant mainly to industrial or research entities.

Summary Table of Cheap CO2 Production Methods

| Method | Description | Cost/Notes |

|---|---|---|

| Buying Dry Ice | Purchase solid CO2 from grocery or specialty stores, sublimates to gas | ~$20 for several pounds, immediate supply |

| CO2 Cylinders | Food-grade or welding cylinders from suppliers | ~$15–20 per 5 lb cylinder, requires regulator |

| Acid + Limestone/Vinegar + Baking Soda | Simple neutralization produces CO2 gas | Very low cost, common household items |

| Citric Acid + Sodium Bicarbonate | Steady CO2 generation for aquariums or experiments | ~$60 for bulk chemicals, long duration |

| Sugar Fermentation with Yeast | Yeast converts sugar to ethanol and CO2 | Cheap supplies, produces impurities |

| Biomass Composting | Organic decomposition yielding CO2 and other gases | Gas impurities, variable quality |

| Point Source Gas Capture | Industrial flue gas scrubbing (~10% CO2) | ~$5/tonne, industrial scale |

| Direct Air Capture (DAC) | Extracts CO2 from ambient air | ~$400/tonne, costly |

| Exhaling | Human breath CO2 source | Free but negligible volume, dilute |

Key Takeaways

- Buying dry ice or CO2 cylinders is a cheap and convenient immediate source.

- Chemical reactions with acids and carbonates (e.g., vinegar and baking soda) yield inexpensive CO2 for small-scale use.

- Citric acid and sodium bicarbonate reactions provide controlled, long-lasting CO2 suitable for applications like aquariums.

- Sugar fermentation using yeast creates CO2 slowly with additional ethanol byproducts, ideal for gradual supply.

- Industrial capture methods exist but require large scale and higher costs to implement.

- Direct air capture methods are currently too expensive for common use.

- Biomass decomposition can release CO2 but the gas mixture often requires complex purification.

How can I produce CO2 cheaply using household items?

You can mix vinegar and baking soda. The acid in vinegar reacts with sodium bicarbonate to release CO2 gas. Eggshells or limestone can replace baking soda for a similar reaction.

Is buying CO2 cylinders a cost-effective option?

Yes. Food-grade or welding CO2 cylinders cost around $15 to $20 for 5 pounds. They are reusable but need proper regulators for safe use.

Can fermentation produce CO2 cheaply and steadily?

Yeast fermentation of sugar makes CO2 cheaply. For example, 2 kg of sugar can produce nearly 300 liters of CO2 in a week. This method suits slow, continuous CO2 supply like hydroponics.

Is thermal decomposition of limestone a practical CO2 source?

It produces CO2 by heating calcium carbonate to ~900°C, but demands high energy and complex setup. This is less practical compared to chemical or fermentation methods.

How does citric acid and sodium bicarbonate compare for CO2 generation?

This reaction offers a controlled CO2 release. It’s safe and can support systems like aquarium injection. Supplies last long and are relatively cheap for consistent production.

Leave a Comment