Removal of Smelly Thiol via Extraction

Thiols can be removed through extraction methods; however, effective removal depends on the chemical environment and functional groups present. Hydroxide extraction converts thiols into water-soluble thiolate salts, but this may hydrolyze esters in your product, making it unsuitable. Alternatively, alkylation followed by bicarbonate extraction or mild acid/base washes can be effective if the product tolerates such conditions.

Hydroxide Extraction and Its Limitations

Extraction with hydroxide (usually NaOH) transforms thiols into thiolate salts. These salts are soluble in water and can be separated from organic phases. This method works well if no hydroxide-sensitive groups exist.

- Hydroxide reacts with thiol (R–SH) forming thiolate (R–S− Na+).

- Thiolate salts are more polar and migrate to aqueous phase.

However, if the product contains esters, hydroxide will hydrolyze them into carboxylate salts and alcohols. This side reaction damages the product, rendering this approach unsuitable.

Alkylation Followed by Bicarbonate Extraction

Thiols can undergo alkylation, converting the sulfur to a derivative with increased polarity.

- Chloroacetic acid or sodium chloroacetate reacts with thiol, forming carboxymethylated thiol.

- The modified thiol contains a free carboxyl functional group.

- Aqueous bicarbonate extraction removes the carboxylate-containing derivative efficiently.

This method allows selective removal while preserving ester groups, making it ideal for ester-containing products.

Use of Mild Acid/Base Washes

Mild extraction methods use dilute alkali (e.g., 0.1 M NaOH) or acid (e.g., 0.1 M HCl) washes.

- NaOH extracts mercaptans by forming thiolate salts.

- HCl extracts basic amines such as triethylamine (TEA) contaminants.

- Product stability under these wash conditions is critical.

This two-step approach removes both thiols and amine impurities, provided that the target molecule resists mild acidic and basic media.

Limitations of Extraction in Odor Removal

Extracting thiols may reduce concentration, but often fails to fully eliminate the odor. Thiol smell is potent, and some residual thiols or transformation products may still be volatile and malodorous.

Additional chemical treatments or alternative purification methods may be required to fully solve odor issues.

Metal Complexation Is Generally Unpreferred

Thiols strongly bind metals like Hg(II), forming insoluble precipitates. Although effective at removal, using toxic metals poses safety and disposal concerns, making this approach impractical for routine purification.

Key Takeaways

- Hydroxide extraction removes thiols but risks ester hydrolysis.

- Alkylation with chloroacetate enables bicarbonate extraction.

- Mild acid/base washes can remove thiols and amines if product is stable.

- Extraction alone may not eliminate thiol odor completely.

- Metal complexation works but is generally avoided due to toxicity.

How to Effectively Remove Smelly Thiol via Extraction?

Removing smelly thiols by extraction is possible, but it requires careful choice of method and often additional steps. Simply put: extraction alone rarely clears the odor, especially when delicate functional groups like esters are present in your product. Let’s dive into the details.

If you’ve ever struggled with the *persistent* and pungent smell of thiols in your lab work, you know the frustration is real. Thiols (mercaptans) are notorious for their foul odors, detectable at incredibly low concentrations. So, how can you whisk these tricky sulfur compounds away?

Extraction with Hydroxide: A Partial Solution but Beware Esters

One common method to tackle thiols is extraction with hydroxide, typically using NaOH. This method works because hydroxide ions deprotonate the thiols, creating thiolate salts. These salts are water-soluble, so they migrate into the aqueous phase, clearing the organic layer.

Sounds good, right? Well, not quite always. Suppose your compound contains esters. Hydroxide, being a strong base, will happily hydrolyze these ester groups, ruining your product. So hydroxide extraction may be off-limits depending on your molecule’s sensitivity.

Think of hydroxide extraction as a selective fighter — effective against thiols but a wrecking ball to esters. Use it when your product lacks delicate ester functionalities and stability allows.

Thiols Meet Alkylation: Turning Trouble into Easy Extraction

Now here’s a clever trick from the chemist’s toolbox: alkylate those thiols first! If your lab stocks chloroacetic acid or even better, sodium chloroacetate, you can modify the thiols via carboxymethylation.

This reaction transforms the smelly thiols into carboxymethyl derivatives bearing free carboxyl groups. Why is that golden? Because these groups increase aqueous solubility, allowing efficient removal by a mild bicarbonate wash.

This two-step dance — alkylation followed by bicarbonate extraction — is especially neat. Why? It removes the odor-causing agent chemically before physically washing it away, rather than relying on extraction alone.

Mild Acid and Base Washes: A Balancing Act

What if your product is somewhat sturdy against mild acid and base? You can attempt sequential washing: first extract mercaptans with 0.1 M NaOH, then eliminate bases like triethylamine (TEA) with 0.1 M HCl.

This approach involves two liquid-liquid extractions, each targeting a different contaminant type. But remember, your product must stay intact through these washes. Otherwise, you’re swapping one problem for another.

Why Extraction Alone Is Not Always Enough

From experience, purification veterans report something important: extraction alone is often insufficient to eliminate thiol odors entirely. Thiols are volatile and potent because their molecules readily travel into the air, smelling up your whole workspace.

Sometimes, even after multiple extractions, traces of thiols cling on, haunting your product and nose alike. So to magic away the smell, additional chemical tricks or alternative methods are best.

Complexation with Metals? Not the First Choice

Thiols love to bind metals, especially heavy ones like mercury(II). Forming precipitates with Hg(2+) is an efficient removal method. But hold your horses — the toxicity and environmental hazards make this method the unpopular kid in the class.

Using mercury compounds just to catch thiols? That’s like bringing a lion to catch mice. Generally, this is neither practical nor safe in most lab or industrial setups.

Non-Extraction Approaches: Really Worth Considering

Since extraction often falls short on odor removal, what else can you do? Several alternatives stand out:

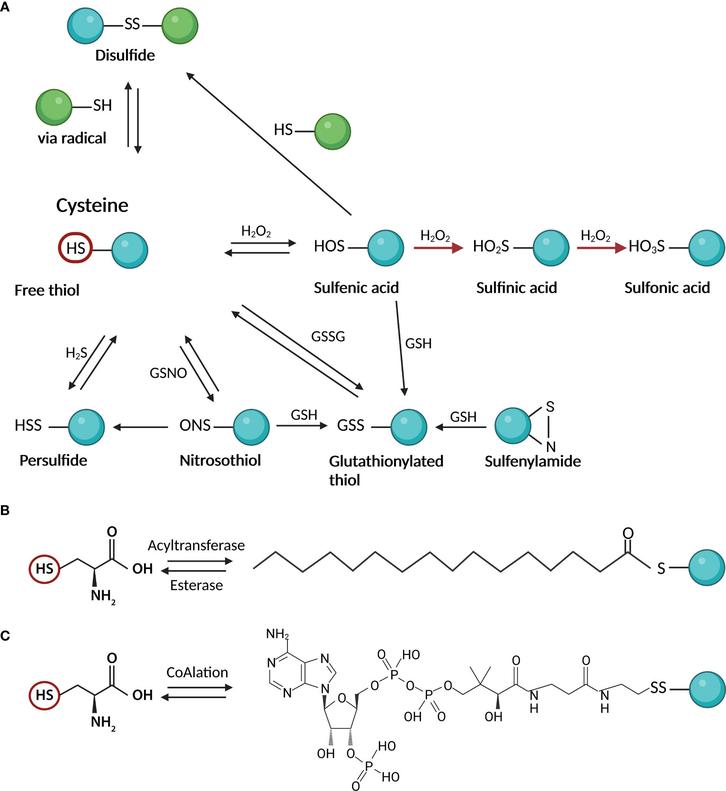

- Selective oxidation by potassium bromate (KBrO3): It converts thiols to disulfides, which still carry smell but less strongly.

- Iodine oxidation with pyridine and KI/I2: Following this, a wash with 1N HCl and sodium thiosulfate or bicarbonate removes iodine and neutralizes acid. This reduces smell effectively.

- Alkylthiosulfonates and S-sulfenylation: These sulfur electrophiles modify thiols chemically, reducing volatility and odor.

- Oxidation with hydrogen peroxide: It transforms thiols into sulfonates, considerably less smelly.

- Distillation under high vacuum (~10 mmHg at ~40°C): Removes volatile thiols physically but requires careful temperature control.

- Bleach in solvent trap during rotavap: An easy hack to neutralize thiol odor as solvents evaporate.

Many of these methods complement extraction, producing cleaner, less smelly products.

Summary Table: Quick Glance at Extraction Methods

| Method | Strengths | Limitations |

|---|---|---|

| Hydroxide Extraction | Efficient for thiol removal if esters not present | Hydrolyzes esters – unsuitable for sensitive products |

| Alkylation + Bicarbonate Extraction | Selective, mild, converts thiols to extractable forms | Requires alkylation reagents and additional steps |

| Mild Acid/Base Washes | Targets thiols and amine bases effectively | Product must resist acidic/basic conditions |

| Extraction Alone | Simple, low-cost | Often insufficient to remove odor completely |

| Metal Complexation | Strong thiol removal | Hazardous, toxic metals involved |

Final Recommendations: Tackling Smelly Thiols Smartly

Removing smelly thiols is a bit like peeling an onion — layers of complexity and no single simple fix. Sure, basic extraction with hydroxide or mild washes might suit simple mixtures without ester groups or sensitive moieties.

But when products are fragile or odors stubborn, chemical modification routes like alkylation or selective oxidation are your best friends. Complement these with extra purification techniques like vacuum distillation or trapping odors during solvent removal.

Try not to rely solely on extraction to solve your stinky situation. A combined approach delivers a cleaner product and fewer lab complaints.

Have you ever tried a quirky lab hack for thiol odor removal? Share your stories – because in chemistry, sharing smelly secrets might just be how we detox the lab atmosphere together.

Q1: Why is extraction with hydroxide not suitable for removing thiols when esters are present?

Hydroxide removes thiols by forming water-soluble thiolate salts. However, hydroxide will hydrolyze esters in your product, damaging the molecule. This makes hydroxide extraction unsuitable when esters exist.

Q2: How does carboxymethylation help in removing smelly thiols via extraction?

Alkylating thiols with chloroacetic acid forms carboxymethylated thiols. These have free carboxyl groups, allowing removal by bicarbonate extraction due to their increased water solubility.

Q3: Can acid and base washes effectively remove thiols and amines together?

Mild base wash (0.1 M NaOH) removes thiols by forming thiolate salts. Acid wash (0.1 M HCl) removes amines like triethylamine. This two-step extraction works if your product tolerates mild acid/base conditions.

Q4: Is extraction alone sufficient to eliminate thiol odor?

Extraction often fails to fully remove the smell of thiols. Thiols are volatile and strongly odorous, so chemical modification or alternative methods are often needed to reduce odor effectively.

Q5: Why are metal complexation methods with mercury ions not commonly used to remove thiols?

Thiols form strong complexes with metals like Hg(II), which can remove them from solutions. Yet, these methods are rarely preferred due to toxicity and handling difficulties.

Leave a Comment