Extracting Oxalic Acid from Rhubarb: A Practical Guide

Oxalic acid can be effectively extracted from rhubarb leaves through a methodical process of blending, boiling, filtration, precipitation, and crystallization, using soluble calcium salts and dilute sulfuric acid to isolate pure oxalic acid. This article guides through each stage, with precise details for a clean extraction.

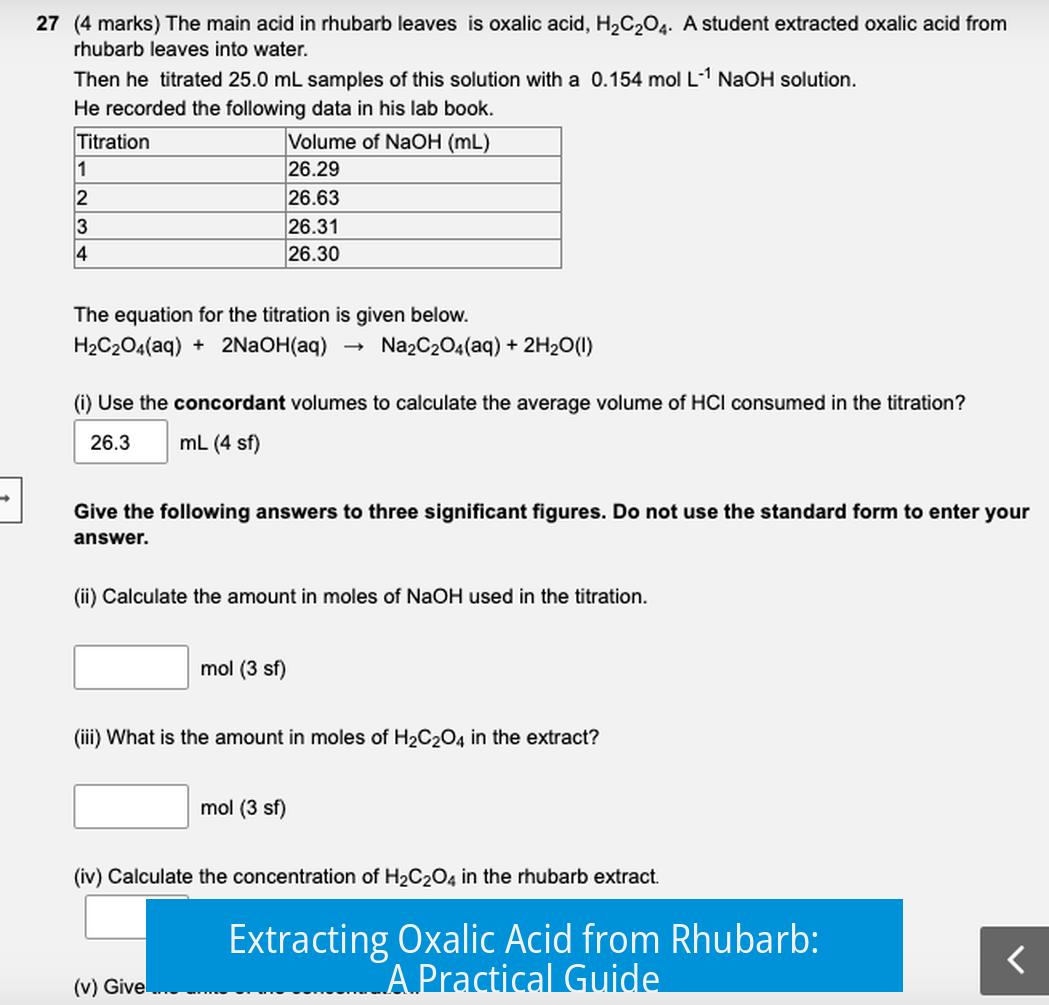

Understanding Oxalic Acid in Rhubarb

Rhubarb leaves contain oxalic acid, an organic compound that acts as a natural plant acid. While oxalic acid is toxic at high levels, it can be extracted for various uses, including cleaning agents or chemical studies. The extraction focuses primarily on isolating oxalic acid from the insoluble plant material and impurities.

Step 1: Preparation of Rhubarb Leaves

Blending over Chopping

Start by processing rhubarb leaves through blending rather than chopping. Blending minces the leaves into a fine pulp more uniformly and increases contact surface area. This step accelerates the extraction of oxalic acid when the material is later boiled. Blending is more efficient than manual chopping and reduces labor.

Boiling Extracts Oxalic Acid Efficiently

Boiling the blended rhubarb pulp in water for a few hours helps leach oxalic acid into the solution. Importantly, boiling doesn’t destroy oxalic acid chemically. This provides a fast alternative to soaking the material for days. Use ample water to allow efficient extraction and avoid too concentrated mixtures that complicate filtration.

- Use clean water and maintain boiling for 2 to 3 hours.

- Carefully monitor volume to prevent excessive evaporation.

- Allow the mixture to cool before filtration.

Step 2: Filtration and Clarification

Multiple Filtration Stages

Post-boiling, the mixture contains soluble oxalic acid and suspended plant fibers. These must be removed through staged filtration:

- First, strain through a coarse sieve to remove large fibers.

- Second, filter through fine muslin cloth to catch smaller particles.

- Lastly, pass through coffee filters for fine clarification.

This multi-tiered approach prevents clogging and yields a clear oxalic acid-containing solution. Direct use of fine filters first results in rapid clogging and inefficiency.

Step 3: Precipitation of Calcium Oxalate

Choice of Calcium Source

To isolate oxalate from solution, precipitate calcium oxalate by adding a soluble calcium salt. Calcium chloride is ideal because it is highly soluble, allowing precise stoichiometric control. Adding too much calcium carbonate (which is insoluble) risks contamination with unreacted calcium salts.

The typical reaction:

CaCl2 (aq) + H2C2O4 (aq) → CaC2O4 (s) + 2 HCl (aq)

Calcium oxalate is sparingly soluble and precipitates out, allowing collection by filtration.

Collecting and Washing the Precipitate

- Filter the mixture to collect solid calcium oxalate.

- Wash the precipitate with cold water to remove soluble impurities.

- Dry the solid before the next step.

Step 4: Final Isolation of Oxalic Acid

Avoid Using Hydrochloric Acid

Regenerating oxalic acid from calcium oxalate using hydrochloric acid (HCl) creates a solution of oxalic acid and calcium chloride, both soluble. This complicates separation and purification due to residual calcium salts.

Use Dilute Sulfuric Acid Instead

Choosing dilute sulfuric acid (H2SO4) converts calcium oxalate into oxalic acid and calcium sulfate:

CaC2O4 (s) + H2SO4 (aq) → H2C2O4 (aq) + CaSO4 (s)

Calcium sulfate is sparingly soluble (approx. 2 g/L) and less deliquescent than calcium chloride. It precipitates out, facilitating filtration and resulting in a purer oxalic acid solution.

Fractional Crystallization for Purification

Because calcium sulfate is not entirely insoluble, fractional crystallization is necessary:

- Filter off calcium sulfate precipitate.

- Concentrate the oxalic acid solution by evaporation.

- Crystallize oxalic acid by cooling the concentrated solution.

- Collect crystals by filtration and dry properly.

This purification improves the purity by removing residual calcium salts.

Alternative and Supplementary Techniques

Concentration via Evaporation

Instead of direct precipitation, some procedures recommend boiling the aqueous extract until almost dry. This method yields a high concentration of oxalic acid as a white powder after removing water. However, this crude extract requires further purification.

Similar Extraction Principles

Techniques resemble the extraction of citric acid from citrus fruits. Demonstration videos on citric acid extraction illustrate the importance of using sparingly soluble calcium salts and staged filtration.

Historical Analogies

Extraction methods for oxalates parallel traditional processes like obtaining lye from wood ashes, where repeated washing, filtering, and precipitation separate useful chemicals from organic matter.

Practical Considerations and Preservation

Longevity of Extracted Oxalic Acid

Pure oxalic acid is stable if stored in a dry, airtight container away from light and moisture. Crystals can retain potency for years under appropriate conditions without decomposition.

Uses of Oxalic Acid from Rhubarb

While rhubarb leaves are toxic due to oxalic acid, extracting it allows safe use of the remaining plant matter. Extracted oxalic acid finds applications in cleaning, metal treatment, and chemical synthesis. Whether rhubarb leaves become “superfood” post-extraction is debatable and not scientifically established.

Utilizing Rhubarb Leaves Fully

Beyond extraction, rhubarb leaves, once free from oxalic acid, may be repurposed for homemade environmentally friendly cleaners. However, caution is warranted due to residual toxicity unless purification is complete.

Summary: Key Points for Extracting Oxalic Acid from Rhubarb

- Blending leaves enhances oxalic acid extraction compared to chopping.

- Boiling does not degrade oxalic acid and speeds up extraction.

- Multi-stage filtration (sieve, muslin, coffee filter) clarifies extract efficiently.

- Use soluble calcium salts (calcium chloride) for calcium oxalate precipitation.

- Dilute sulfuric acid is preferred over hydrochloric acid for regenerating oxalic acid.

- Fractional crystallization improves purity by removing calcium sulfate.

- Proper storage of pure oxalic acid ensures stability and longevity.

- Extraction opens potential uses for rhubarb leaves beyond direct consumption.

How can I efficiently extract oxalic acid from rhubarb leaves?

Blend the rhubarb leaves to create a pulp. Boil this pulp in water for several hours. This method speeds up extraction and preserves oxalic acid since boiling does not destroy it.

Why use multiple filtration steps when extracting oxalic acid?

Staged filtration removes plant fibers and fine particles gradually. Start with a sieve, then muslin fabric, and finish with coffee filters. Filtering directly with coffee filters clogs them quickly.

Which calcium compound is best for precipitating calcium oxalate?

Use calcium chloride because it is soluble. Insoluble calcium carbonate can contaminate your product if used in excess since it won’t dissolve completely in the solution.

Why is dilute sulfuric acid preferred over HCl for isolating oxalic acid?

Dilute sulfuric acid forms calcium sulfate, which is sparingly soluble and easier to separate by filtration. HCl would leave you with soluble calcium chloride and oxalic acid, making separation difficult.

What steps ensure a pure oxalic acid product after precipitating calcium oxalate?

Filter off most calcium sulfate formed with sulfuric acid. Then perform fractional crystallization to separate oxalic acid from minor impurities, as the calcium sulfate is only slightly soluble and precipitates first.

Leave a Comment