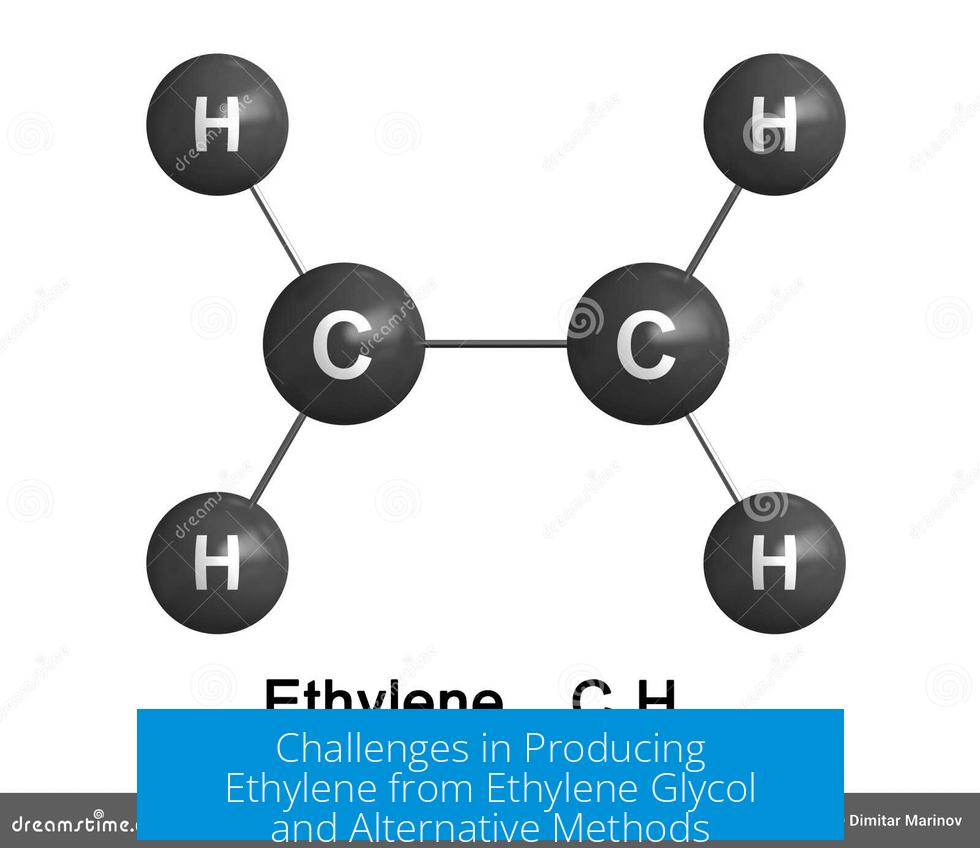

Producing ethylene from ethylene glycol presents considerable challenges, primarily due to the oxidation state of ethylene glycol and the complexity of required equipment and processes. Ethylene glycol is already partially oxidized, which complicates its conversion into ethylene, a reduced hydrocarbon. This mandates a catalytic process that includes a reduction step, adding layers of difficulty.

Challenges in Ethylene Production from Ethylene Glycol

Complex Equipment and Preparation

Research indicates that existing methods to convert ethylene glycol to ethylene demand highly specialized and complex apparatus. Laboratory procedures listed in databases like Reaxys show intricate setups that are not straightforward for routine or large-scale production.

Oxidation State Complications

Ethylene glycol, being partially oxidized, requires a catalyst system that not only breaks down the molecule but also reduces it to ethylene. This reaction is not simple; it involves a delicate balance of oxidation and reduction steps that must be precisely controlled.

Need for Reductants or Coupled Reactions

Such catalytic processes usually consume a reductant or require coupling with oxygen or hydrogen peroxide (H2O2) generation to maintain the catalytic cycle. This coupling adds complexity and potentially increases cost and safety concerns during operation.

Alternative Ethylene Production Methods

Dehydration of Ethanol

A more viable alternative is the dehydration of ethanol to produce ethylene. This reaction is well researched, more straightforward, and uses simpler catalysts and equipment. It is widely used in industry with established protocols.

Purchasing Ethylene

If the goal is to obtain ethylene rather than focus on its synthesis from ethylene glycol, procuring ethylene gas directly from industrial suppliers is often more practical. This avoids complex synthesis issues and reduces labor and equipment costs.

Summary

- Ethylene production from ethylene glycol involves complex catalytic reduction steps due to its oxidized state.

- Specialized equipment and reductants or coupled oxygen/H2O2 systems complicate the process.

- Dehydration of ethanol offers a simpler, well-studied route to ethylene.

- Buying ethylene gas directly often saves resources and hassle.

How challenging is it to produce ethylene from ethylene glycol?

Producing ethylene from ethylene glycol requires complex equipment. The preparation methods are not simple and often need specialized tools.

Why does the oxidation state of ethylene glycol complicate its conversion to ethylene?

Ethylene glycol is already in an oxidized form. To convert it to ethylene, a reduction step is necessary, adding complexity to the process.

What additional substances are needed when converting ethylene glycol to ethylene?

A reductant is required, or the process must be coupled with oxygen or hydrogen peroxide generation. This makes the catalytic cycle more complex.

Is there a simpler method to produce ethylene than using ethylene glycol?

Yes, dehydration of ethanol to produce ethylene is more straightforward. This method is well-studied and easier to implement.

Should one consider buying ethylene instead of producing it from ethylene glycol?

Purchasing ethylene gas from a supplier can save time, cost, and labor. It may be more practical than attempting the conversion process.

Leave a Comment