Flex Seal: What Is It?

Flex Seal is a range of adhesive products designed to seal leaks and cracks by forming a flexible, waterproof barrier upon curing. It consists mainly of styrene butadiene copolymer, pigments, solvents, and curing agents. Different types of Flex Seal vary in composition and curing mechanisms.

Types of Flex Seal and Their Differences

- Petroleum Solvent-Based: This type dries as the solvent evaporates, forming a protective seal. It requires time to set after application due to solvent removal.

- Silicone-Based: Contains siloxane/oxime compounds that cure by cross-linking in the presence of moisture in the air.

The choice of type affects how the product cures and performs in various environments.

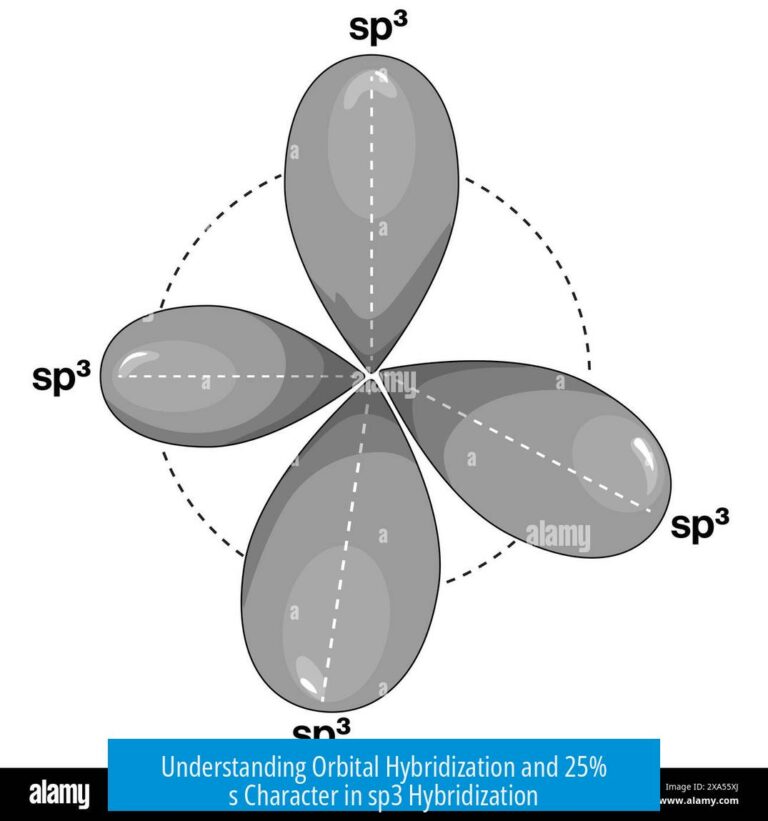

Chemical Composition and Curing

Flex Seal’s primary polymer is styrene butadiene copolymer. Pigments and activators adjust color and facilitate cross-linking. The curing mechanism depends on moisture or solvent evaporation:

- Silicone-based types cure faster in high humidity or elevated temperatures due to moisture-activated crosslinking.

- The moisture-induced curing aligns with established crosslinking systems widely used in coatings and sealants.

Safety and Handling Considerations

Users must exercise caution due to the chemical properties of Flex Seal products:

- Not recommended during pregnancy.

- Low flash point means exposure to open flames is dangerous.

- Skin irritation potential—wear gloves to prevent contact.

Applications and User Experience

Flex Seal finds uses in household repairs and some industrial applications. The manufacturer recommends consulting them for large-scale industrial use. This ensures access to proper guidance and samples.

Users report success in sealing leaks, such as pools with ports leaking. Combining Flex Seal liquid with waterproof tape and allowing 24 to 48 hours of curing yields effective water-tight seals.

Reference Documentation

Material Safety Data Sheets (MSDS) provide detailed chemical and safety information:

| Type | MSDS Link |

|---|---|

| Petroleum Solvent-Based | View MSDS |

| Silicone-Based | View MSDS |

Key Takeaways

- Flex Seal products use different chemical bases, including petroleum solvent and silicone systems.

- They form flexible, waterproof seals by solvent evaporation or moisture-activated crosslinking.

- Proper handling requires safety precautions due to flammability and skin irritation risks.

- Consult manufacturers for industrial uses to ensure correct product selection and application.

- User reports confirm effectiveness when applied properly and allowed to cure fully.

What are the different types of Flex Seal and how do they work?

There are multiple types of Flex Seal. One type is petroleum solvent based and dries by evaporating the solvent. Another is silicone based, curing through moisture in the air via a cross-linking process.

What is the chemical makeup of Flex Seal?

Flex Seal is styrene butadiene copolymer based, containing pigments, activators, and solvent. Silicone types have siloxane/oxime and cure faster with humidity or heat.

What safety precautions should I take when using Flex Seal?

Do not use Flex Seal if you are pregnant. It has a low flash point, so avoid flames. It can irritate skin, so wearing gloves is recommended.

How should Flex Seal be applied for effective results?

Let it dry for 24 to 48 hours between coats. For leaks, layering Flex Seal liquid over waterproof tape can form a strong seal. Industrial users should consult the company for advice and samples.

Where can I find detailed safety information about Flex Seal products?

Material Safety Data Sheets for petroleum solvent based and silicone based Flex Seal can be found online. These sheets provide comprehensive safety and handling instructions.

Leave a Comment