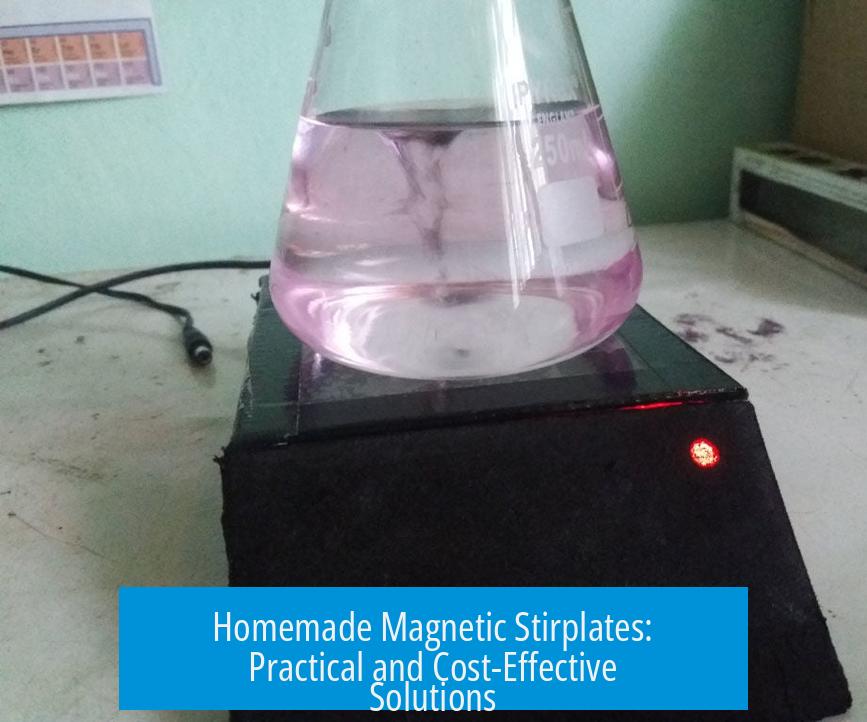

Homemade Magnetic Stirplates: Practical and Cost-Effective Solutions

Homemade magnetic stirplates offer affordable and efficient stirring options for hobby chemists and homebrewers by combining simple electronics with readily available components. These DIY devices often perform as well as, or better than, commercial units costing over $1000. Several designs focus on stir plates alone or combined with heating capabilities.

1. Stir Plate with Hot Plate Combo

A notable design uses a computer fan controlled by a PWM 555 timer circuit to vary stirring speed. Affixed to the fan is a strong N52 neodymium magnet. This creates the magnetic field necessary to drive a stir bar inside a reaction vessel. Suggested improvements include replacing the timer circuit with a microcontroller and adding optical or hall effect sensors. This would allow precise speed control essential for repeatable experiments.

Heating employs two 300W 3D printer heater cartridges embedded within a 7″x7″x1″ aluminum block. The aluminum bar serves as the heat distribution medium. The block must be machined to house the cartridges neatly; though challenging, it can be achieved at home with care and proper tools. Temperature control is managed via an inexpensive Chinese PID controller, enabling fast and accurate temperature settings. This setup reportedly outperforms many expensive commercial hot plates.

The entire unit costs less than $100, significantly reducing the financial barrier for hobby chemists. The designer offers to share detailed plans for non-commercial use, fostering accessibility and knowledge sharing within the community.

2. Homebrew Stir Plates

Magnetic stir plates also find popularity among homebrewers. These devices help initiate and maintain yeast cultures during fermentation. By providing consistent stirring, the plates improve yeast health and fermentation reliability. This crossover underscores the broad applications and appeal of homemade stir plates outside traditional laboratories.

3. Mini Stir Bar for Glovebox Use

Another compact design involves a hobby motor with a bar magnet enclosed in plastic. This mini stir bar fits inside gloveboxes where controlled atmospheres are required. Although it lacks heating capability, it serves well for stirring tasks in inert environments. The entire build costs approximately $15, emphasizing low-cost solutions tailored to specific needs.

Key Advantages and Community Engagement

- DIY stirplates leverage inexpensive parts like computer fans, magnets, and printer heater cartridges.

- Using PID controllers grants precise temperature control comparable to commercial models.

- Modular designs allow customization, such as adding microcontroller-based speed control.

- Sharing plans non-commercially supports hobbyist chemistry and homebrewing communities.

Summary of Key Points

- Magnetic stir plates can be effectively homemade using computer fans and neodymium magnets for stirring.

- Combining heating elements like 3D printer cartridges with aluminum blocks offers fast, even heating.

- PID temperature controllers enable precise temperature management rivaling commercial units.

- Designs exist for both full stir plate-hot plate combos and mini stir bars for specialized environments.

- Plans and designs are shared freely to reduce cost barriers in hobby chemistry and related fields.

What components are used to build a homemade magnetic stirrer?

A computer fan is used as the base, with an N52 neodymium magnet epoxied to it. The fan speed is controlled by a PWM 555 timer circuit. This setup creates the stirring magnetic field.

How is temperature controlled on a DIY hot plate for stir plates?

Heating is done with 3D printer heater cartridges embedded in an aluminum block. A PID temperature controller manages the heat, allowing precise and quick temperature settings.

Can I build a magnetic stir plate on a tight budget?

Yes. The total cost for a combined stirrer and hot plate can be under $100, much cheaper than professional units that cost over $1000.

How can I improve speed control on a homemade stirrer?

Replace the 555 timer with a microcontroller and add an optical or hall effect speed sensor. This allows setting and maintaining specific stirring speeds more accurately.

Is it possible to make a stirrer for special environments like gloveboxes?

Yes. A mini stir bar can be built using a hobby motor with a bar magnet inside a plastic case. It costs about $15 and does not include heating.

Leave a Comment