How Does Oil Dry? Does It Dry Through Evaporation or Oxidation?

Oil dries primarily through the process of oxidation rather than evaporation. While minor evaporation of solvents or lighter components may occur, the key mechanism that transforms oil from liquid to solid is the chemical reaction of the oil molecules with oxygen. This reaction leads to polymerization and crosslinking, effectively hardening the oil into a solid form.

Understanding What ‘Drying’ Means for Oils

The term “drying” has different meanings depending on the type of oil and the context. For example, drying a vegetable oil like olive oil is not the same as drying drying oils used in painting or woodworking, such as linseed oil.

In many cases, drying refers to how the oil changes from a liquid state to a solid or semi-solid film. This transformation does not happen merely by the removal of moisture or evaporation of volatile components, as is typically the case with water-based materials.

The Role of Evaporation in Oil Drying

Evaporation plays a minor supporting role in the drying process for oils that are mixed with solvents or thinner substances. For example, oil-based paints or wood finishes often contain volatile solvents that evaporate quickly after application.

- As these solvents evaporate, the remaining oil becomes more concentrated and viscous.

- This evaporation can contribute to an initial tackiness or partial drying but does not cause complete hardening.

- In some vegetable oils, evaporation of light fragrance compounds or minor constituents may occur, affecting aroma but not drying per se.

Thus, solvent evaporation facilitates hardening indirectly by removing diluents and allowing oxidation to proceed more effectively on the concentrated oil.

Oxidation: The Primary Drying Mechanism

The dominant drying process for oils such as linseed, tung, or walnut oil is oxidation. This involves a chemical reaction between the unsaturated (double-bonded) fatty acid chains in the oil and oxygen from the air.

During exposure to oxygen:

- Double bonds in oil molecules react, forming reactive epoxides and hydroperoxides.

- These reactive intermediates initiate a radical chain reaction, often triggered further by ultraviolet light or heat.

- Subsequent polymerization links these oil molecules into long, crosslinked chains.

- The molecular weight rises significantly as a solid polymer network forms.

This network transforms the oil into a tough, insoluble film rather than merely drying by losing a solvent or evaporative component.

Chemical Details of Oxidation and Polymerization

Oxidation progresses through stages:

- Initial Oxidation: Formation of hydroperoxides at the sites of unsaturation.

- Propagation: Hydroperoxides break down into radicals, which attack neighboring molecules.

- Polymerization and Crosslinking: Radical intermediates cause oil molecules to form covalent bonds, crosslinking fatty acid chains.

- Solid Film Formation: The crosslinked polymer network grows and hardens into a solid.

This process is slow and may take days or weeks, depending on factors such as temperature, humidity, and oil type.

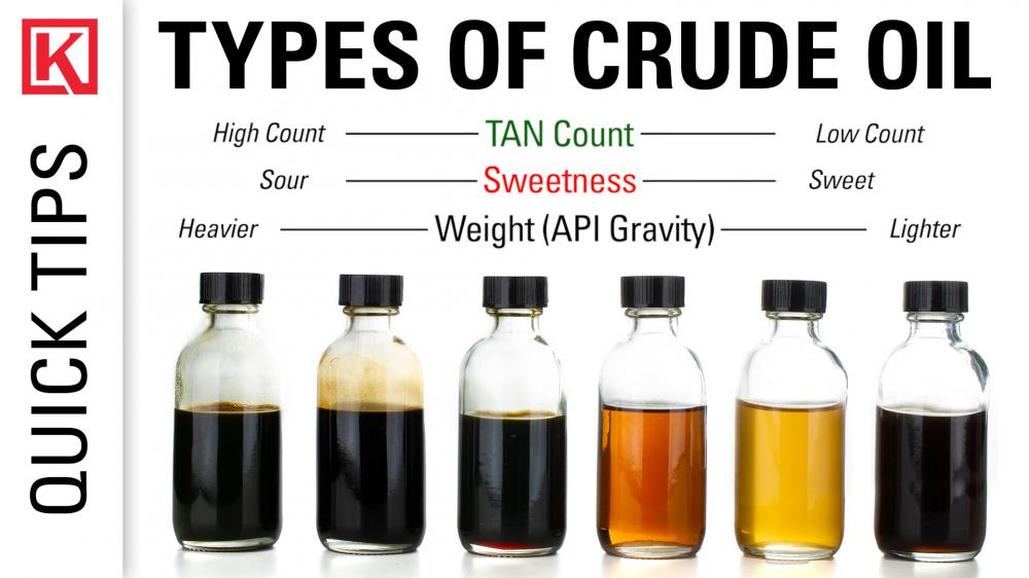

How Different Oils Dry

Not all oils dry by oxidation. Oils rich in polyunsaturated fatty acids (many double bonds) tend to oxidize and form solid films. Those with fewer double bonds, such as some saturated oils, remain liquid and do not dry appreciably.

| Oil Type | Drying Mechanism | Tendency to Dry |

|---|---|---|

| Linseed Oil | Oxidation and polymerization | High – dries to a solid film in days/weeks |

| Tung Oil | Oxidation and crosslinking | High – durable, fast-drying |

| Olive Oil | Evaporation of volatiles and minimal oxidation | Low – remains mostly liquid |

| Vegetable Oils (saturated) | Minimal oxidation, no polymerization | Low – does not dry |

The Influence of Additives and Catalysts

In commercial products, additives and catalysts often accelerate oxidation and polymerization. For example, wood finishes based on drying oils may include metal salts (driers) that catalyze oxygen uptake.

Additionally, solvents thin the oil to improve penetration and application. These solvents evaporate quickly, leaving a higher concentration of oil to oxidize more efficiently.

Environmental Factors Affecting Oil Drying

Oxidation is influenced by several environmental conditions:

- Temperature: Higher temperatures increase reaction rates.

- Humidity: High humidity can slow oxidation by limiting oxygen diffusion.

- Airflow: Good ventilation enhances oxygen availability and solvent evaporation.

- Light Exposure: Ultraviolet light can spur radical formation, promoting drying.

Thicker oil layers take longer to dry because oxygen cannot penetrate deeply, delaying polymerization throughout the film.

Why Oil Paint Takes Longer to Dry

Oil paints dry slowly because the drying process depends on oxidation and polymerization rather than evaporation alone. Without solvent evaporation being the primary mechanism, the elapsed time is required to complete multiple chemical reactions forming crosslinked polymers.

Careful control of environmental factors and use of catalysts can reduce drying times.

Summary of Key Points

- Oil drying mainly occurs through oxidation, not evaporation.

- Evaporation of solvents or minor volatile components supports drying but is not the main mechanism.

- Oxidation involves reaction of oil double bonds with oxygen, forming polymers and resulting in hardening.

- Not all oils dry; only those rich in unsaturated fatty acids undergo oxidation and polymerization.

- Additives and catalysts can speed the drying process.

- Environmental conditions such as temperature, humidity, and airflow impact drying time.

- Oil paint drying is slower due to reliance on chemical reactions rather than evaporation.

How Does Oil Dry? Does It Dry Through Evaporation or Oxidation?

Answer: Oil dries primarily through oxidation rather than evaporation. But hold on—this isn’t the simple “just wait and it disappears into thin air” kind of drying. It’s a combo dance featuring evaporation of some solvents and a slow, chemistry-heavy oxidation process that transforms the oil from liquid to solid.

If you ever wondered why your linseed oil finish or oil paint takes forever to dry, it’s no accident. The oil itself doesn’t vanish by evaporating like water or alcohol. Instead, it undergoes a fascinating chemical metamorphosis that hardens the film.

The Many Flavors of “Drying”: What Do We Mean by Dry?

First, let’s clarify what “drying” means. It depends on the kind of oil and what’s mixed with it. Vegetable oils differ greatly from oil paints or wood finishing oils like linseed oil. Some oils have solvents added to them. When those evaporate, it feels like the oil has dried. But the true drying for oils is a change on a molecular level—where the liquid becomes solid by reacting with oxygen.

For example, linseed oil, popular in woodworking and artists’ paints, is usually thinned with volatile solvents to help it soak into wood or mix well with pigments. Those solvents evaporate quickly, leaving a surface that seems dry to the touch.

Evaporation: The Quick Exit of Solvents

Solvent evaporation is the fastest part of the drying process. When you spread an oil-based varnish on wood, you might notice the surface dry within minutes. This is mostly because the solvents are evaporating. Think of solvents as the “fast runners” speeding off quickly. Once they’re gone, the oil doesn’t run off or evaporate easily.

For vegetable oils like olive oil, lighter molecules that produce aroma and flavor can evaporate, causing oil to smell less fresh over time. But these are minor players irrelevant to the oil’s structural drying.

Oxidation: The Molecular Dance that Hardens Oil

Here comes the star of the show: oxidation. Oils, especially drying oils like linseed, contain molecules with double bonds. When exposed to oxygen, these bonds react and form epoxides—curious molecules that link together. This crosslinking turns the once fluid liquid into a tough polymer network, effectively turning oil into a solid film.

This process is slow and can even be sped up by adding catalysts or dryers that woodworking products often include. It’s akin to a molecular handshake party where oil molecules hold hands tightly, leaving behind a hard protective layer on wood or canvas.

Why Isn’t Evaporation Enough? Why The Long Wait?

You might ask: If evaporation is fast, why does paint or oil take days to fully “dry”? Because evaporation only removes the solvents. The oil’s base, composed of fatty acid chains, needs to undergo oxidation, forming those polymer chains that mesh together into a solid. This chemistry is slow and depends on temperature, humidity, and thickness of the applied layer.

Oil paint’s notorious long drying time isn’t a flaw. It’s a property of oxidation and polymerization. Unlike water or acrylic paint, which dry by losing water instantly, oil paints cure by this chemical hardening step.

What Affects Oil Drying Time?

- Thickness: Thicker layers take longer to oxidize and harden fully.

- Environmental Factors: Warm temperatures and moderate humidity speed up oxidation.

- Additives: Catalysts or drying agents can accelerate the oxidation process significantly.

For instance, artists sometimes add small amounts of cobalt or manganese dryers to speed up drying. Woodworkers use products with catalysts and solvents to balance penetration and drying time.

A Tale of Two Oils: Oxidizing vs. Non-Oxidizing Oils

Not all oils dry the same way. Oils rich in double bonds—like linseed, tung, and walnut oil—oxidize well. Others, like olive oil, have fewer double bonds and don’t polymerize effectively. These oils stay liquid longer and resist forming solid films. It’s why olive oil doesn’t work well as a varnish.

So, the drying process also hinges on the chemistry of the oil itself.

Putting It All Together

Drying oils like linseed oil dry mainly through oxidation, where oxygen reacts with double bonds turning the oil into a solid film. Evaporation plays its part by removing solvents or other volatile compounds, which helps the oil soak and start solidifying faster.

When you rub linseed oil into your furniture, the solvent evaporates quickly, leaving behind the oil. Oxygen from the air then slowly oxidizes the oil, causing molecular crosslinking that toughens and hardens the surface. This slow chemical reaction makes oil finishes so durable and long-lasting.

Have You Checked Your Oil Products?

Wondering why your project or painting doesn’t dry fast? Take a peek at the label. Does it mention solvents? Any drying agents? Knowing the balance between solvents and oxidation catalysts can help you pick the right product for your needs.

And remember, patience is key. Your oil finish isn’t lazy; it’s busy undergoing molecular magic!

Practical Tips

- For quicker drying, apply thinner layers—oxidation happens on the surface first.

- Maintain a warm, dry environment to speed oxidation without causing cracking.

- Use products with added dryers if time is tight.

- Choose drying oils (like linseed or tung) for protective finishes, not just any cooking oil.

Summary Table: Evaporation vs. Oxidation in Oil Drying

| Aspect | Evaporation | Oxidation |

|---|---|---|

| What dries? | Solvents and volatile substances | Oil molecules (with double bonds) |

| Speed | Fast (minutes to hours) | Slow (hours to days) |

| Result | Removes liquid, leaves oil behind | Forms polymer, hardens oil |

| Effect on durability | Minimal | Creates strong, resistant finish |

| Controlled by | Temperature, airflow | Oxygen availability, catalysts |

In conclusion, oil doesn’t just sneak out as vapor and disappear. It performs a slow, fascinating choreography with oxygen that turns it from a runny liquid to a solid protective layer. Next time you watch oil dry on wood or canvas, you’re witnessing a microscopic hardening party where molecules bond and lock together, thanks to oxidation.

How does oil paint dry if the oil itself doesn’t evaporate?

Oil paint dries through oxidation, not evaporation. The oil reacts with oxygen in the air, which causes it to harden into a solid by forming polymers.

Does evaporation play any role in drying oil-based products?

Yes, solvents or thinner present can evaporate, which helps the oil soak into surfaces and leaves behind a harder layer. However, the oil itself dries by oxidation.

What exactly happens to the oil molecules during the drying process?

The double bonds in the oil oxidize and form epoxides. These react further to crosslink and polymerize, increasing molecular weight and turning liquid oil into solid film.

Do all oils dry through oxidation?

Only oils with many double bonds oxidize effectively. Oils with fewer or no double bonds do not dry well and remain mostly unchanged.

What factors affect the drying time of oil paints?

Temperature, humidity, and paint thickness influence how fast oxidation occurs. Catalysts or additives in some oils can also speed up the drying process.

Leave a Comment