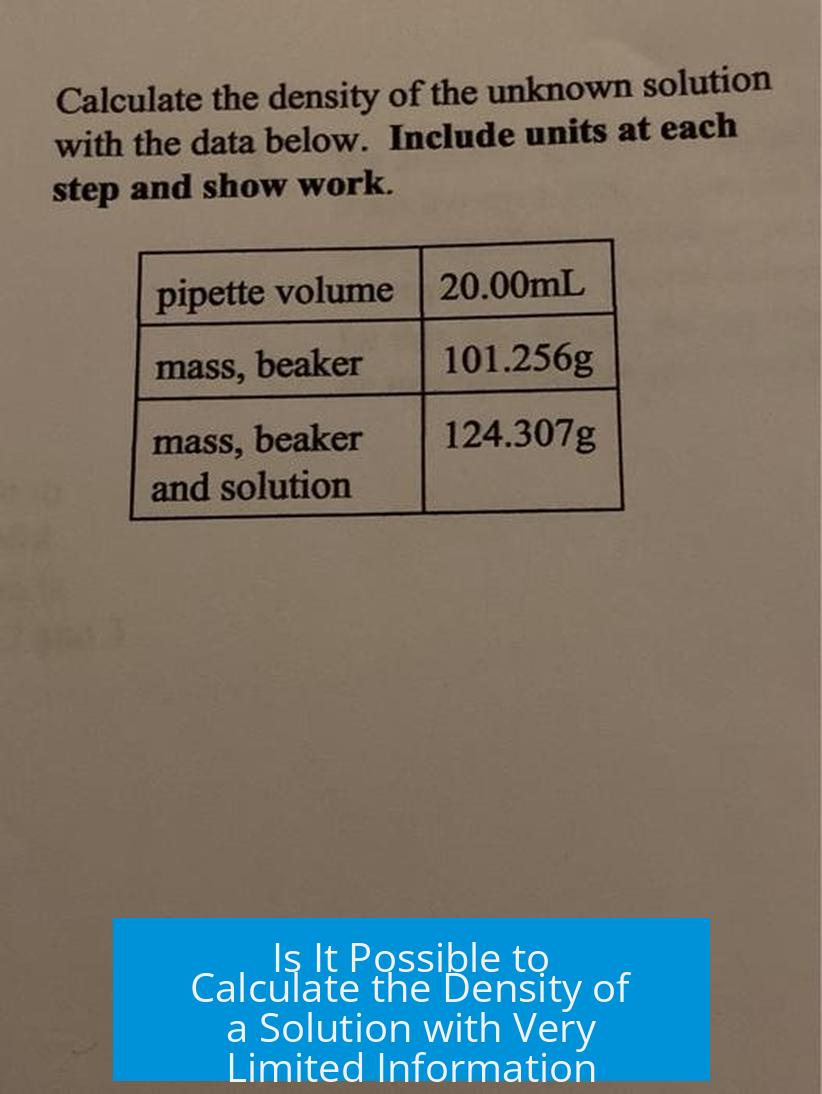

Is It Possible to Calculate the Density of a Solution with Very Limited Information?

Yes, it is possible to estimate the density of a solution with limited information, but precise calculation requires more detailed data. The best practical approach is to use a weighted average of the constituent densities, while acknowledging some potential error.

Measurement vs Estimation

Direct measurement remains the most reliable method to determine the density of a solution. However, when measurement is not feasible, estimation techniques must be applied cautiously.

Volumes in mixtures are not always additive. For example, mixing 50 mL of substance A with 50 mL of substance B may yield less than 100 mL total volume due to molecular interactions and volume contraction. This complicates direct volume-based calculations of density.

Composition Ambiguity

Understanding the composition and phase behavior of the solution is critical. Whether the solution is 20% oil in water or 20% water in oil, and if it forms a single phase or an emulsion, affects the density estimation.

Industrial lubricants often contain complex components and may not be soluble in water, potentially forming emulsions or two-phase mixtures. The physical state influences how accurate simple estimation methods will be.

Weighted Average Approach

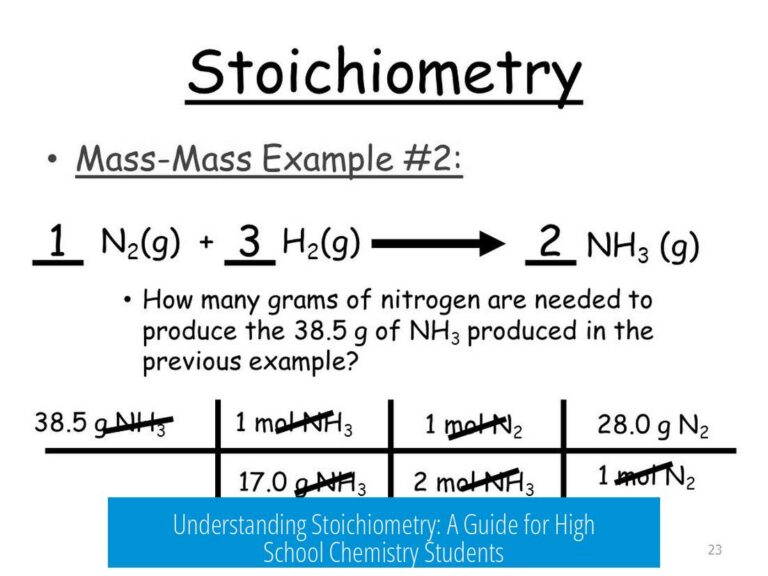

The commonly applied estimation method involves taking the weighted average of the densities of the pure components:

- Density estimate = (fraction of component A × density of A) + (fraction of component B × density of B)

This method assumes no reaction or volume change upon mixing. It generally provides a result within 10-20% of the actual density for two-phase mixtures or weakly interacting components.

For instance, mixing 20% oil (density 1.05 g/cm3) with 80% water (density 1.00 g/cm3) yields an estimated density of approximately 1.01 g/cm3:

(0.20 × 1.05) + (0.80 × 1.00) = 1.010 g/cm3

If mixing is by mass instead of volume, volume contraction may slightly affect the result but typically retains similar values (e.g., about 1.0096 g/cm3).

Theoretical Calculation Limitations

Accurately computing solution density requires detailed data such as partial molar volumes, temperature-dependent behavior, and concentration effects. Such data are often unavailable or impractical to obtain for complex industrial mixtures.

Therefore, theoretical methods are seldom applied with limited information. Estimations serve as the most feasible alternative but must be treated as approximate.

Complex Lubricant Composition

If the lubricant contains emulsifiers or surfactants creating stable emulsions, deviations in density may occur. However, these effects tend to be minor unless the mixture significantly changes volume or phase behavior.

Key Takeaways

- Direct measurement of density is most reliable but not always possible.

- Volume changes upon mixing limit additive volume assumptions.

- A weighted average of component densities provides a reasonable estimate.

- Estimated densities may differ by up to 10-20% from true values.

- Complex mixtures require advanced data to compute density accurately.

- Estimation works best for two-phase systems or weakly interacting solutions.

Can density be accurately calculated with limited data on solution composition?

Not accurately. You can estimate density using weighted averages of densities for each component. But accuracy suffers if the solution’s exact composition and mixing behavior are unclear.

What challenges arise from unclear solution composition?

Knowing whether the percentage is oil in water or water in oil matters. Also, whether the mixture is a single phase or separates affects density calculations a lot.

Is using weighted average a reliable method for density estimation?

It gives a rough estimate within about 10-20% error for simple mixtures. Engineers often accept this due to limited data, but chemists find it less precise for single-phase solutions.

Why can’t theoretical density be calculated with limited information?

Theoretical calculation needs detailed data like partial molar volumes at various temperatures and concentrations. Without this, estimations are the best option.

How do volume changes upon mixing affect density estimation?

Volumes aren’t fully additive. Combining 50 mL of each liquid might not yield 100 mL total volume, which can lead to errors if volume changes aren’t accounted for.

Do complex lubricants affect density estimates?

Complex lubricants with surfactants might cause slight variance in density. But usually, this variance is small enough to be ignored for rough calculations.

Leave a Comment