Is It Safe to Work With Polyurethane?

Working with polyurethane is generally safe when proper precautions and safety protocols are followed because the original toxic components, isocyanates, are converted into less harmful prepolymers before reaching the workplace.

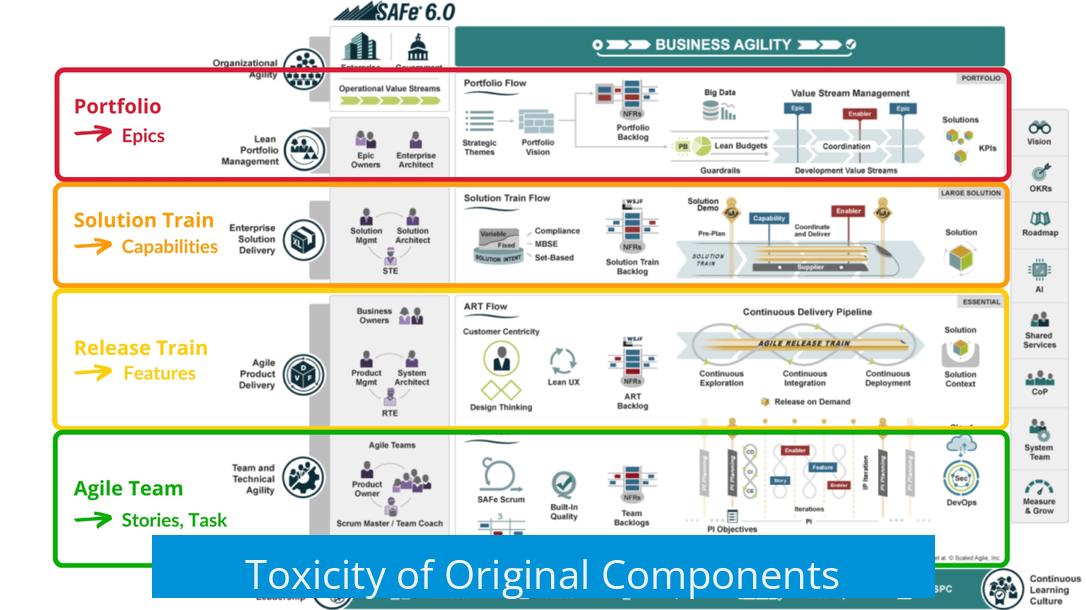

Toxicity of Original Components

The primary raw materials in polyurethane production are isocyanates. These chemicals are highly toxic and can cause respiratory issues and skin irritation. Direct exposure to isocyanates poses significant health risks.

Conversion to Safer Substances

Before polyurethane products, such as foams, are made, isocyanates undergo chemical reactions to form prepolymers. These substances are much less dangerous and are what workers typically handle in manufacturing settings.

Because isocyanates are processed into prepolymers before the product reaches the workplace, employees are not directly exposed to the most toxic materials. This transformation considerably reduces workplace hazards.

Concerns About Residual Isocyanates

Although prepolymers are safer, there may be concerns about residual isocyanate monomers or incomplete foaming. These factors could lead to trace exposures during handling. Testing protocols should verify the extent of such residues.

- Test final products for residual chemicals regularly.

- Be cautious with large foam slabs and finished items like earplugs.

Hazards of Burning Polyurethane

Burning polyurethane releases toxic chemicals, including harmful gases. This process poses severe risks. Avoid thermal degradation or burning of polyurethane products in any occupational environment.

Workplace Safety and Training

Effective safety training is essential. Employers should provide comprehensive information on handling, exposure risks, and emergency responses. Workers must voice their concerns and receive clear answers.

Monitoring Chemical Concentrations

Concentration levels of residual chemicals can vary over time, especially within the first days after production. Continuous monitoring of these levels ensures workplace safety and helps control exposure.

Key Takeaways

- Pure isocyanates are toxic; however, they are converted into safer prepolymers before workplace use.

- Proper handling and safety protocols minimize exposure risks.

- Residual isocyanates and incomplete foaming require regular testing.

- Burning polyurethane releases toxic substances and must be avoided.

- Safety training and communication are vital to safe working conditions.

- Monitoring residual chemical concentrations, especially early on, enhances safety.

Leave a Comment