THC Distillate Dripping: Comprehensive Overview

THC distillate dripping involves the application and visualization of a highly viscous, concentrated cannabinoid extract derived through intricate extraction and distillation processes. This distillate represents a refined cannabinoid fraction characterized by exceptional purity, separated from terpenes, lipids, and other impurities via controlled vacuum distillation techniques.

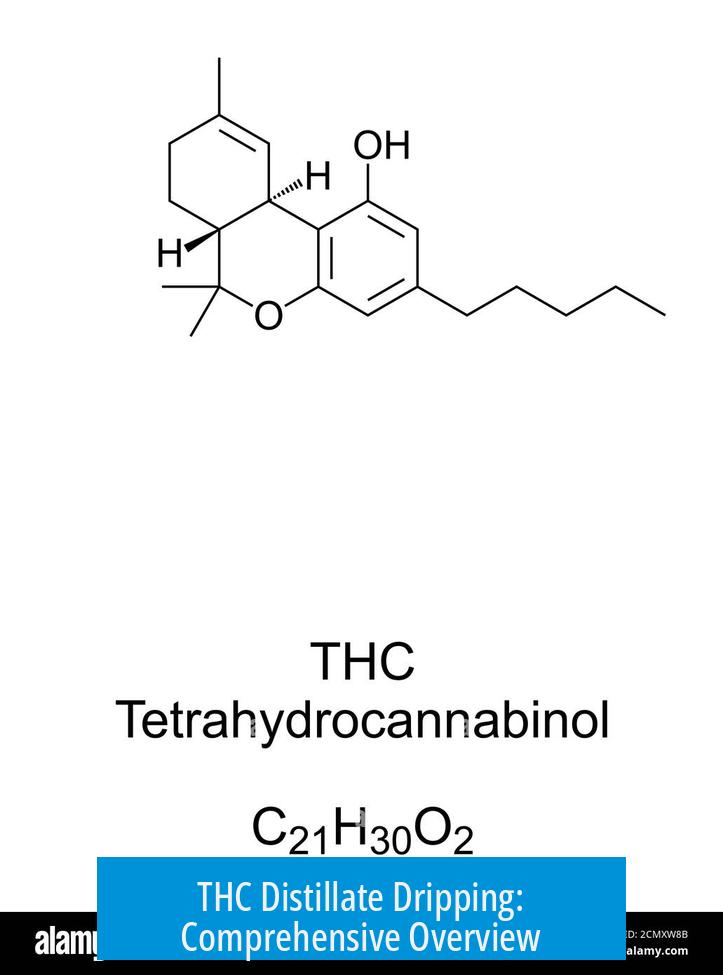

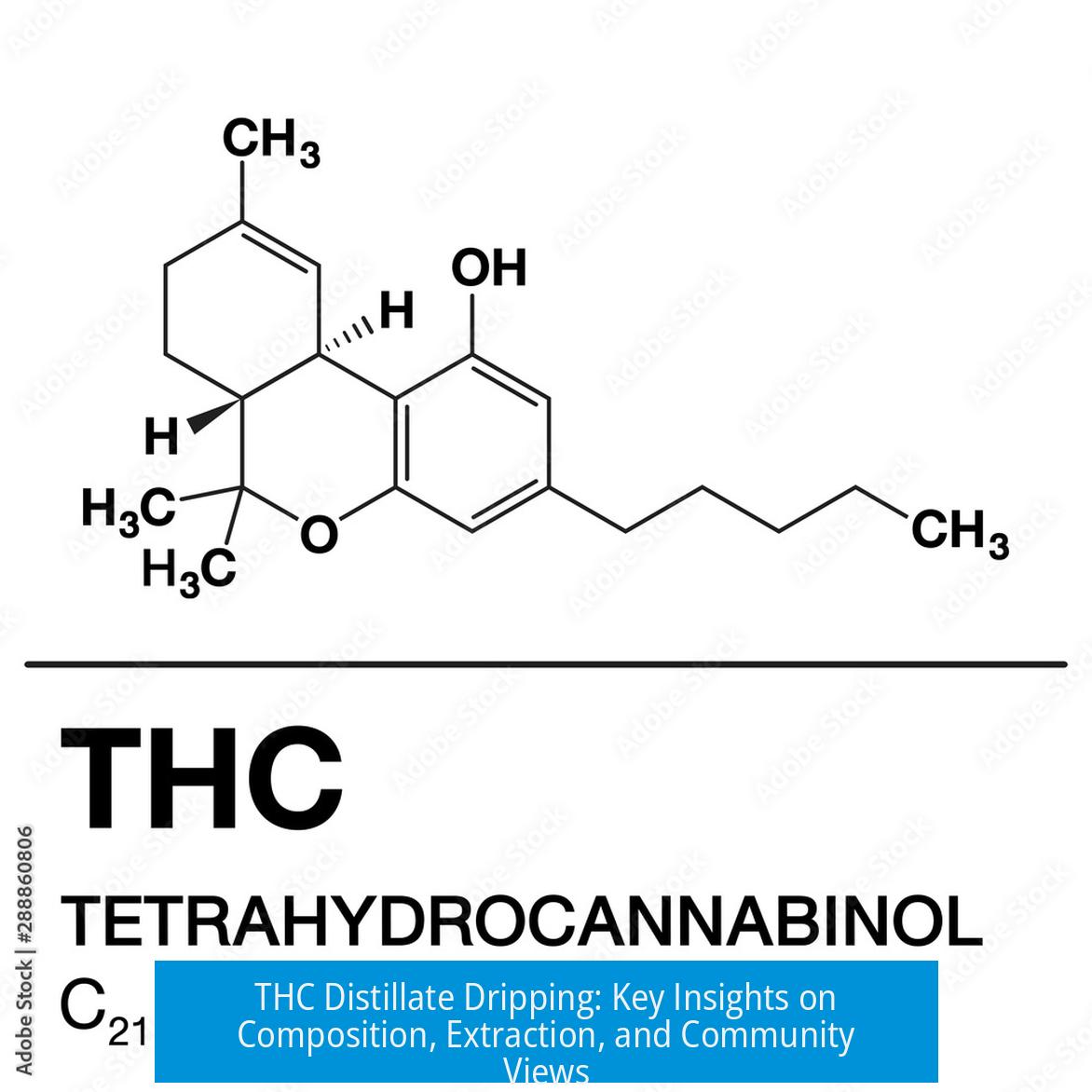

Composition and Physical Nature of THC Distillate

THC distillate is a thick, amber to golden-colored substance chiefly composed of concentrated tetrahydrocannabinol (THC) and other cannabinoids. It exhibits high viscosity, often described as syrupy or honey-like. This consistency results from the removal of non-cannabinoid compounds, lipids, and solvents.

Typically, the produced distillate is not a pure THC isolate. Instead, it contains a cannabinoid-rich fraction which can exceed 90% purity. The physical behavior during dripping is notable; the viscous liquid may form curling shapes reminiscent of a “slinky,” demonstrating surface tension and flow dynamics influenced by its density and molecular interactions.

Extraction of Cannabinoids from Biomass

The production of THC distillate begins with cannabinoid extraction from cannabis or hemp biomass. Popular extraction methods include:

- Ethanol/Alcohol Extraction — utilizes ethanol as a solvent to dissolve cannabinoids.

- Hydrocarbon Extraction — employs butane, propane, or similar hydrocarbons for cannabinoid solvation.

- CO2 Extraction — supercritical carbon dioxide extraction is favored for its tunable parameters and cleaner profile.

Post-extraction, hydrocarbon or CO2 extracts undergo winterization. This step cools the mixture between 0°C and -40°C for 24 to 48 hours, precipitating lipids and waxy materials. Subsequent filtration removes these insoluble impurities, improving extract clarity and purity.

Solvent Removal and Decarboxylation

Following extraction and winterization, solvent removal ensures that residual ethanol, hydrocarbons, or CO2 are eliminated. Techniques include rotary evaporation, falling film evaporation, or membrane filtration. Complete solvent removal is critical for safety and product integrity.

Decarboxylation transforms acidic cannabinoid precursors (e.g., THCA) into their active neutral forms (THC). This reaction occurs in vacuum reactors, where heat and reduced pressure facilitate efficient conversion and further solvent evaporation.

Vacuum Distillation Techniques for THC Isolation

The core process for producing THC distillate is vacuum distillation under ultra-low pressures. This reduces cannabinoids’ effective boiling points, enabling separation without thermal degradation, which is crucial given THC’s high boiling temperature.

Industrially, thin film evaporation (also known as wiper or roller film evaporation) stands out for its efficiency and scalability. Alternatively, short path distillation or spinning band distillation units may be employed on smaller scales.

Vacuum levels are achieved using roughing pumps such as rotary vane or dry scroll pumps (e.g., Edwards E2-m80). These are often supplemented by diffusion pumps for deeper vacuum. Turbo molecular pumps have been tested but risk mechanical failures.

The distillation process involves two main passes:

- First Pass: Removal of terpenes and lighter volatile compounds.

- Second Pass: Isolation of cannabinoids, yielding the distillate.

Purity and Fractionation Post-Distillation

The distillate formed is a high-purity cannabinoid fraction separated from non-cannabinoids. Typical purity levels exceed 90%, but the fraction is not chemically pure THC. Crude distillates may retain minor cannabinoids and trace impurities.

To achieve isolated THC, further purification using chromatographic techniques such as centrifugal partition chromatography (CPC) or flash chromatography may be applied. These methods isolate individual cannabinoids, pushing purity near 99.9%.

Emerging industry trends focus on crystallizing THCA as a precursor to high-purity THC. This approach bypasses some distillation limitations and provides pharmaceutical-grade cannabinoid isolates.

Challenges and Misconceptions Regarding THC Distillation

A common misunderstanding involves THC’s boiling point and distillability. Since THC has a higher boiling point than water, many question its volatility. Vacuum distillation addresses this by lowering effective boiling points at reduced pressures, enabling cannabinoid separation without degradation.

Extraction quality can vary. For example, insufficient cold during winterization can cause unwanted chlorophyll extraction, leading to reddish instead of golden distillates. Controlling temperature, time, and solvent purity is critical for quality control.

Visual Characteristics During Dripping of THC Distillate

When THC distillate drips, its behavior illustrates its physical properties. The liquid may form curling, jet-like shapes resembling a “slinky,” reflecting its surface tension and viscous flow. These dynamics help to visually confirm the consistency and purity of the concentrate.

Community Perceptions and Varied Opinions

Within the cannabis community, opinions about THC distillate vary. Some identify variations like Delta-8 THC distillates distinct from Delta-9 THC. Others question the natural origin, labeling some products as synthetic or adulterated. Despite this, distillates garner attention for their potency, clarity, and versatility.

Summary of Key Points

- THC distillate is a viscous, high-purity cannabinoid concentrate, produced via multi-step extraction and vacuum distillation.

- Extraction methods include ethanol, hydrocarbon, and CO2 techniques, typically followed by winterization to remove lipids.

- Ultra-low vacuum distillation (thin film or short path) separates terpenes and cannabinoids effectively.

- Distillate purity is generally above 90%; chromatography can isolate pure THC if needed.

- THC distillate exhibits unique dripping behavior due to its viscosity and surface tension.

- Vacuum conditions lower THC’s boiling point, enabling distillation despite misconceptions.

- Extraction temperature control is critical to prevent chlorophyll contamination.

- Industry advances include THCA crystallization for ultra-pure cannabinoid products.

What causes the distinctive “slinky” shape when THC distillate drips?

The curling “slinky” shape occurs due to the distillate’s high viscosity and flow properties. Its thick, sticky nature creates these unique patterns as it falls before disappearing.

How does vacuum distillation help separate THC in the distillate process?

Vacuum distillation lowers the boiling points of cannabinoids, allowing THC and others to vaporize without high heat. This separates cannabinoids from lighter compounds like terpenes in a two-step distillation.

Is THC distillate pure THC or a mixture?

THC distillate is a high-purity cannabinoid mixture, not pure THC. It separates cannabinoids from heavier impurities, but further purification like chromatography is needed for isolated THC.

Why is temperature control important during extraction for THC distillate?

Proper cold temperatures prevent chlorophyll and unwanted pigments from dissolving into the extract. Without this control, the distillate color can shift from golden amber to an undesirable red.

What equipment is commonly used for industrial THC distillate production?

Thin film evaporation plants are most common, often paired with short path or spinning band distillation units. These use ultra-low vacuum pumps to separate cannabinoids effectively during distillation.

Leave a Comment