Easy and Cheap Preparative TLC with Regular TLC Plates

Preparative thin-layer chromatography (prep TLC) can be efficiently performed using regular TLC plates made in-house. This method involves coating scratched plain glass slabs with a silica gel suspension containing CaSO4 (F254), drying, and baking the plates. It provides a low-cost, practical way to purify milligram-scale samples with good resolution.

Materials Required for Homemade Preparative TLC Plates

- Glass slabs (20 x 20 cm): Simple window glass works well as a base, avoiding expensive specialized plates.

- Silica gel with CaSO4 (F254): Silica gel containing the F254 indicator is commercially available and not costly. The indicator aids monitoring sample progress.

- Water: Used to suspend silica gel for even coating on glass slabs.

- Glass rod: Helps spread the silica suspension uniformly over the glass surface.

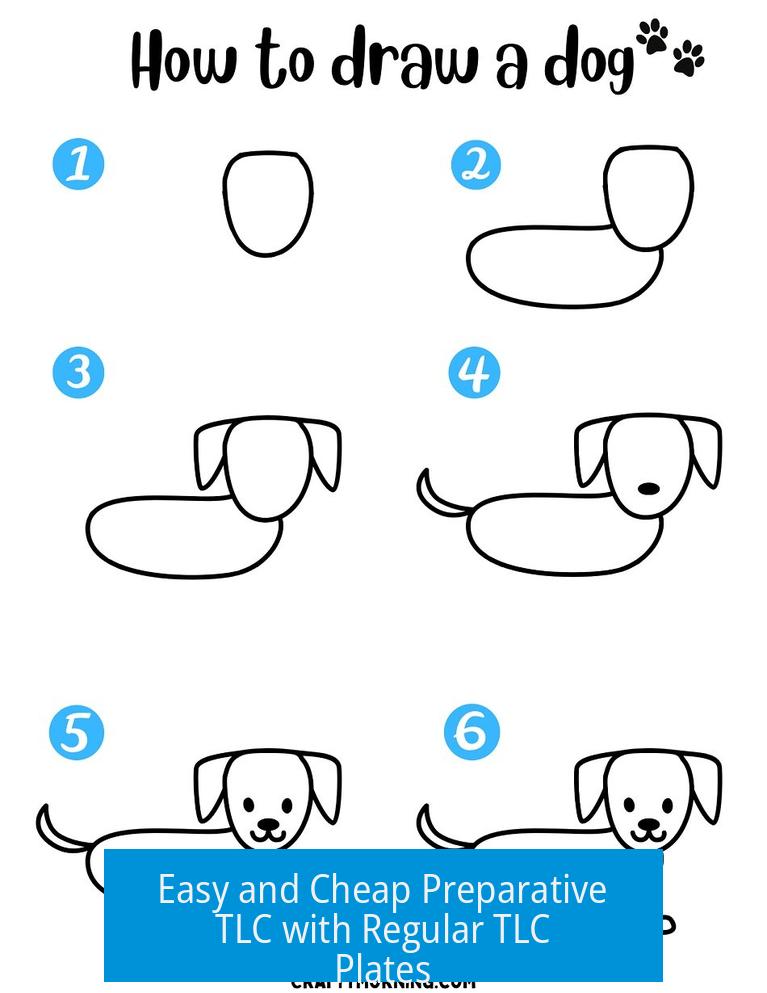

Stepwise Preparation of Plates

- Surface preparation: Thoroughly scratch or sand glass slabs to enhance adhesion. This roughness allows the silica layer to stick reliably during use.

- Silica suspension: Combine 140 g of silica gel containing CaSO4 with 750 mL of water. Mix thoroughly to form a uniform suspension.

- Coating: Pour 60–70 mL of the silica suspension per glass slab. Use the glass rod to spread the slurry evenly, pulling towards edges to avoid uneven thickness.

- Drying and baking: Let plates dry overnight at ambient temperature. Cure them in an oven at 120 °C for at least two hours to fix the silica layer firmly.

One batch of suspension can coat approximately eight plates, making this method scalable and cost-efficient.

Sample Application and Loading Capacity

Each prep TLC plate can handle sample loads of about 150–200 mg. Dissolve the crude mixture in roughly 0.8 mL of dichloromethane (DCM) or another suitable solvent. Apply the sample carefully, ensuring complete solvent evaporation before starting chromatography. This prevents band distortion during development.

Elution and Recovery of Components

After development, the separated zones are scraped off and extracted by leaching with acetone heated to 50 °C. Repeating the extraction three times improves recovery of the purified compounds.

Applications and Limitations

This homemade prep TLC approach suits purification of small quantities (3 to 10 mg) of compounds displaying modest separation on analytical TLC but challenging to purify by column chromatography. It offers a practical alternative for researchers lacking access to preparative HPLC or costly commercial prep TLC plates.

However, if compounds separate well on TLC, column chromatography generally provides superior resolution and yield. Thus, preparative TLC is a supplementary method useful for samples ill-suited to columns.

Considerations Regarding Silica Gel with F254

The fluorescent indicator (F254) in silica gel is helpful for visualization but may raise concerns about interference with purification or detection results. Generally, the indicator layer does not impair compound separation or recovery in prep TLC. It remains a standard additive in most commercial and homemade plates.

Summary of Key Points

- Scratch window glass slabs to improve silica gel adhesion.

- Mix 140 g silica gel-CaSO4 (F254) with 750 mL water for suspension.

- Spread 60–70 mL suspension per plate using a glass rod for uniform coating.

- Dry plates overnight; bake at 120 °C for 2+ hours to fix silica layer.

- Load 150–200 mg sample dissolved in ~0.8 mL solvent per plate.

- After running TLC, leach separated bands with heated acetone (50 °C) three times.

- Method effectively purifies 3–10 mg components hard to separate by columns.

- Silica gel with F254 indicator does not interfere in purification or analysis.

Leave a Comment