Is BPA-free Polycarbonate Possible?

Yes, BPA-free polycarbonate is possible by replacing bisphenol A (BPA) with alternative diols in the polymer synthesis. Manufacturers have developed polycarbonates using other diol compounds that maintain desirable material properties while avoiding BPA. This approach offers a viable path toward polycarbonates free from BPA monomer.

Alternative Diols for BPA-Free Polycarbonates

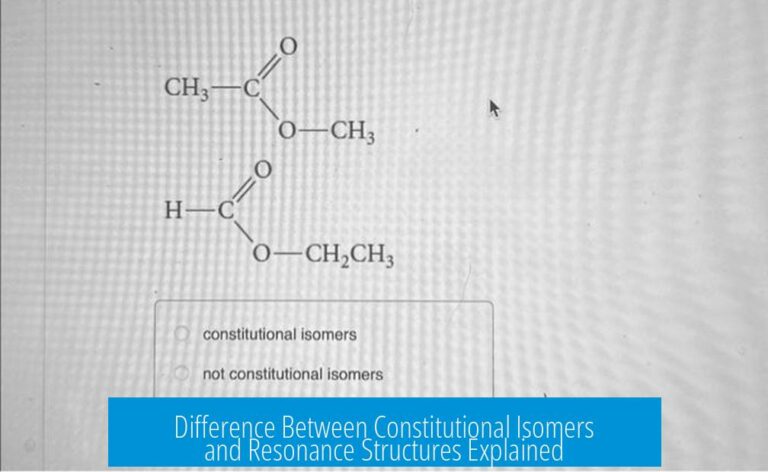

Polycarbonates form through the reaction between diols and carbonate linkages. BPA is a common diol used, but many others have been tested:

- 1,1-Bis(4-hydroxyphenyl)cyclohexane: Introduced as a comonomer to reduce crystallization in BPA-based polymers, improving processability.

- Dihydroxybenzophenone: Another diol tested, often to provide specific physical traits.

- Tetramethylcyclobutanediol: Developed as a direct BPA substitute, allowing creation of BPA-free polycarbonate with similar mechanical and thermal properties.

These alternatives enable manufacturing a range of polycarbonates with varied properties, since the term “polycarbonate” refers to any polymer with carbonate linkages, not solely those made with BPA.

Understanding BPA-Free Labeling

The “BPA-free” label generally means BPA is below detection thresholds or allowable limits. Trace BPA residues may remain in polymers despite this designation due to production processes and analytical sensitivity.

Complete removal of BPA monomer ensures safety concerns related to BPA exposure are minimized. However, as polymers differ significantly from their monomers, the behavior and risk profile of polycarbonates depend on both chemical composition and final structure.

Chemical Properties of BPA and Polycarbonates

It is crucial to differentiate between monomers like BPA and the resulting polymer. The chemical and physical properties of polycarbonates are distinct from those of BPA monomers. Polymerization alters reactivity, molecular mobility, and overall stability.

This distinction means that even BPA-based polycarbonates tend to be inert compared to free BPA monomer, affecting considerations about safety and material performance.

Summary of Key Points

- BPA-free polycarbonates are achievable by substituting BPA with other diols.

- The polycarbonate family includes many polymers, not limited to BPA variants.

- “BPA-free” means very low or undetectable BPA concentrations, not absolute absence.

- Properties of polycarbonates differ significantly from BPA monomers themselves.

Leave a Comment