How to Turn Stainless Steel Black?

Stainless steel turning black through traditional black oxide methods is challenging due to its corrosion-resistant properties. However, several approaches exist to achieve a black finish, though results vary from carbon steel coatings.

Challenges with Stainless Steel Blackening

Unlike carbon steel, stainless steel resists forming oxide layers. This resistance stems from the chromium content in stainless steel, which creates a stable and protective surface oxide layer. Therefore, conventional black oxide treatments, well-suited for carbon steel, do not perform efficiently on stainless steel.

Why Black Oxide Works Better on Carbon Steel

- Black oxide finish (black iron oxide) forms via chemical reaction, typically using ferric chloride (FeCl3). This creates a thin, blackened surface layer.

- Carbon steel readily forms this oxide coating, especially when heat-treated and submerged in oil baths, enhancing the finish.

- Stainless steel’s surface chemistry and oxide layer prevent similar coatings from bonding well and uniformly.

Possible Methods for Blackening Stainless Steel

- Anodizing: This electrochemical process can color stainless steel in hues including black. However, it produces different aesthetics than the classic black oxide on carbon steel and requires specialized equipment.

- Chemical Blackening Solutions: Some commercial products like Niblack 40 can be brushed on stainless steel, producing a black finish. The process involves applying the solution and then washing it off, forming a thin dark layer.

- Heat and Oil Treatments: While these work well for carbon steel, they offer limited effect on stainless steel’s appearance due to its oxide layer protection.

Additional Tips and Considerations

- Ensure steel type: Black oxide coatings are more suited for high-carbon steels than stainless steel.

- Surface preparation improves finish quality—clean and possibly roughen the steel surface before treatment.

- Expect differences: Black finishes on stainless steel might appear less uniform or less intense than on carbon steel counterparts.

Summary of Key Points

- Black oxide finish is common for carbon steel but rare and difficult on stainless steel.

- Stainless steel’s corrosion resistance impedes traditional oxide coating formation.

- Anodizing and chemical treatments like Niblack 40 offer alternative blackening methods.

- Blackening results on stainless steel differ visually and chemically from carbon steel finishes.

How to Turn Stainless Steel Black? PLEASE HELP

Turning stainless steel black is a tricky business because stainless steel resists oxidation, making traditional black oxide finishes difficult to achieve. So, if you want that classic “blackened” look, don’t expect the same results as with carbon steel. But don’t despair! There are still ways to give stainless steel a dark, sleek finish that looks sharp and maintains durability.

Let’s dig into the nitty-gritty of why stainless steel is stubborn about black coatings and explore practical tips to get that coveted black finish.

Why Black Oxide Works on Carbon Steel but Not Stainless Steel

Black oxide finishes are popular in metalworking, especially with high-carbon steels. This finish comes from black iron oxide, a chemical reaction that forms a protective, corrosion-resistant layer. The secret sauce? Ferric chloride (FeCl3), often brewed from steel wool and muriatic acid in blacksmith circles for its effectiveness.

Here’s the kicker: stainless steel hates forming oxide coatings. That’s why it’s called stainless—it resists rust and oxidation better than your average steel. Its chromium content forms a passive layer that repels the oxidizing process needed for black oxide coatings to stick around.

Think of stainless steel as that one friend who just *won’t* get sunburned no matter how long they stay outside. You can try to tan them, but good luck getting a proper burn!

What About Anodizing Stainless Steel?

Anodizing can tweak stainless steel’s surface to create some color changes and textures. However, it’s more like giving your blade a light suntan rather than a deep, rich black oxide. The results differ from the deep black oxide finish seen on carbon steel. So, if your goal is the classic blacksmith style dark patina, anodizing falls short.

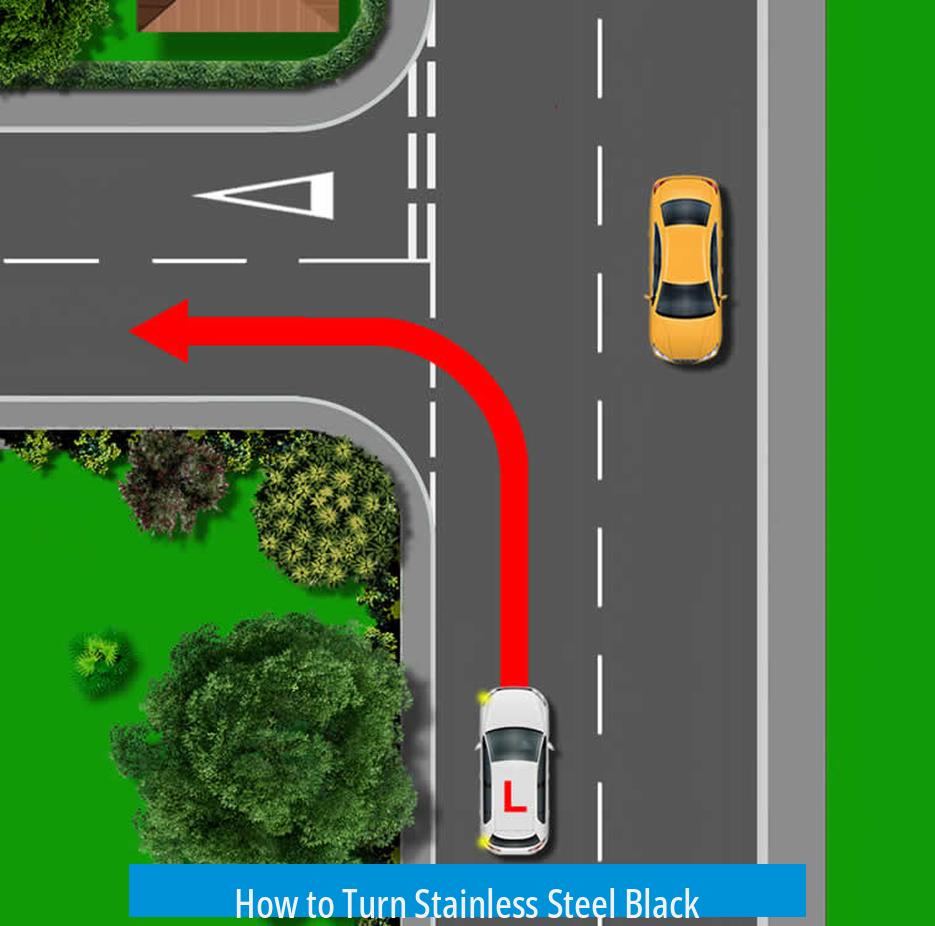

The Oil Bath Trick after Heat Treating

If you’re heat-treating blades, plunging them into an oil bath afterwards can add a faint oxide layer. It’s a bit like giving the steel a quick spa treatment that leaves a subtle ‘tint’ on its surface. Usually, this coating is polished off for a shiny finish.

But if you leave it unpolished, it can look darker—often serving as a rough, matte “blackening” effect. Just don’t expect it to be the full-on black oxide coating that carbon steel can show off.

Is that Black Finish Just ‘Unpolished Stainless’? Sometimes, Yes!

Sometimes stainless steel looks dark simply because it’s not polished after forging. That dull, blackened look isn’t chemical but just unfinished metal. So if your shiny stainless steel suddenly looks moody black, ask yourself: “Did I polish this or not?” It’s not fancy chemistry, just skipped finishing.

Using Specialty Products for Stainless Steel Blackening

If you want to get serious about blackening stainless steel, you can try Niblack 40. This solution brushes on and washes off, leaving a blackened finish. It’s practical for stainless steel, given the challenges of oxide-based methods. Niblack 40 works as a convenient, mostly surface-level coating that can give you the look without the fuss.

Why Do Carbon Steels Benefit More?

Imagine carbon steel like 1095 as the eager student of oxidation—it forms neat oxide layers easily. These layers boost corrosion resistance and add vintage charm. Stainless steel doesn’t need this help because it already resists rust inherently. So black oxide coatings on stainless aren’t necessary or even very practical.

Summing It Up: Practical Tips to Turn Stainless Steel Black

- Don’t expect classic black oxide: Stainless steel won’t behave like carbon steel in chemical reactions for black oxide layers.

- Try anodizing—but keep expectations realistic: It changes the surface but doesn’t create deep black finishes.

- Consider the oil bath finish: Heat treat then plunge in oil to add subtle darkening, especially if you leave the finish unpolished.

- Use specialty coatings like Niblack 40: Applies easily and yields a decent blackened appearance for stainless.

- Understand material limits: Stainless steel’s corrosion resistance reduces the need and effectiveness of coatings that work on carbon steel.

So, next time you’re eyeballing your stainless steel project thinking, “How do I get that blackened, mysterious look?” remember: you’re wrestling with a material built to resist it. But armed with oil baths, anodizing, and smart coating products, you can get surprisingly close.

Still wondering? Think like a blacksmith—sometimes the trick isn’t brute force but knowing your metal’s personality. What method will you try first to turn your stainless steel dark? Drop your thoughts and let’s crack this blackening mystery together!

Can you achieve a black oxide finish on stainless steel like on carbon steel?

Stainless steel resists forming oxide coatings, unlike carbon steel. You can’t get the same black oxide finish on stainless steel with standard black oxide methods.

What chemicals are used for blackening carbon steel, and do they work on stainless steel?

Ferric chloride is used for black oxide on carbon steel. It doesn’t work well on stainless steel because it doesn’t form the necessary oxide layer.

Are there alternative methods to turn stainless steel black?

Anodizing can be used on stainless steel, but it won’t create the deep black look seen on carbon steel. You can also try solutions like Niblack 40 for surface darkening.

Does heat treatment affect the color or finish of stainless steel?

Heat-treating followed by an oil bath can create some oxide coating on carbon steel blades. For stainless steel, this effect is minimal and usually does not produce a black finish.

Is polishing important in achieving a black finish on steel?

Unpolished steel can look darker after forging, but polishing usually removes oxide layers. Leaving the steel unpolished can help maintain a darker appearance after treatments.

Leave a Comment