Is There a Difference in Quality Between Recycled Cotton/Polyester and New Cotton/Polyester?

The quality of recycled cotton/polyester blends generally matches that of new (virgin) blends once processed correctly. Differences depend mainly on the type of recycling and manufacturing adjustments, but final textile properties such as strength and durability are comparable.

Quality Comparison Overview

Recycled cotton/polyester fabrics often deliver similar performance to new blends. The key lies in the recycling method and how manufacturers adjust yarn thickness or fabric weight. When done properly, recycled fabrics show identical abrasion resistance, tensile strength, and stain resistance as virgin materials.

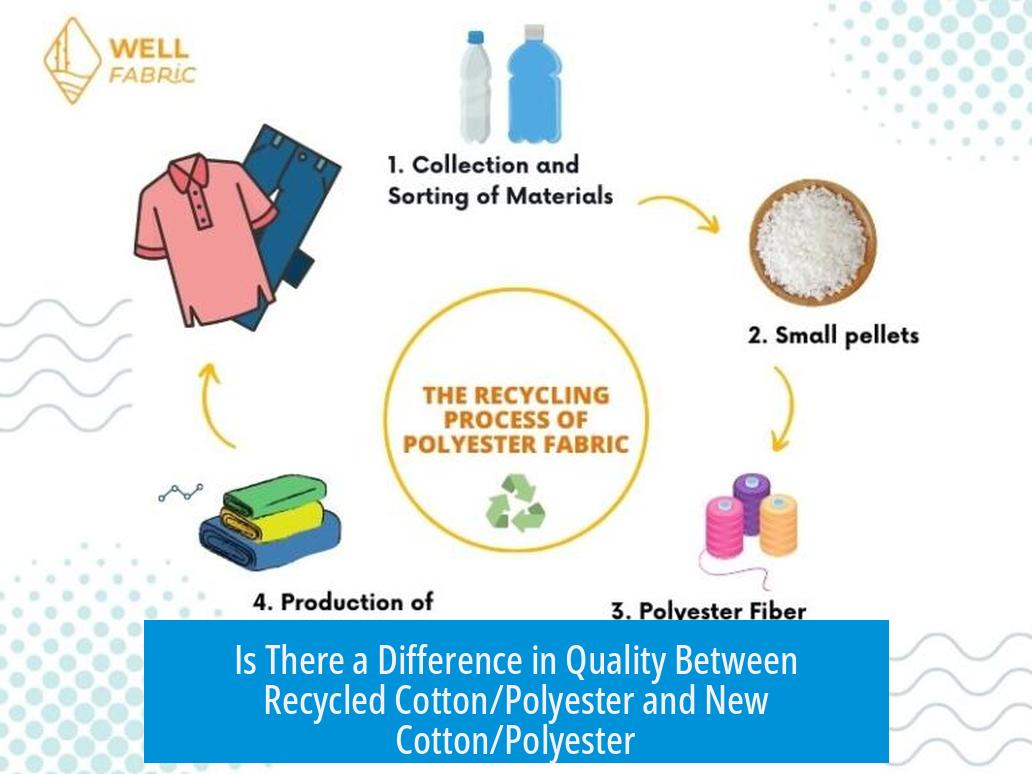

Recycling Processes Affect Quality

- Chemical Recycling: This method breaks down polyester into basic monomers (depolymerization), allowing for very high-quality fiber production. However, it remains rare due to high costs. Companies like Circ (formerly Tyton) use combined chemical recycling for polyester and cellulose blends.

- Mechanical Recycling: More common and less expensive, it involves washing, shredding, melting, and spinning polyester from used products like plastic bottles. Though the fiber quality is slightly lower initially, manufacturers offset this by thicker yarns or fabric.

Adjusting Fabric to Ensure Quality

Since mechanically recycled fibers may start weaker, clothing makers use thicker yarns or denser fabrics to maintain expected durability. This ensures the end product feels and performs like virgin blends to consumers.

Blending with Other Fibers

Recycled polyester yarn often blends with cotton or nylon to improve fabric characteristics. The blending process twists different yarns together to create stronger, more versatile textiles, identical in feel to new fiber blends.

Cleaning and Preparation of Recycled Fibers

Before recycling, plastic polyester sources undergo extensive washing with water and possibly mild sterilizing agents like bleach or peroxide. This removes contaminants without harmful additives, ensuring clean polyester suitable for textile use. For example, approximately five recycled plastic bottles produce enough polyester for one t-shirt.

Key Takeaways

- Recycled cotton/polyester blends match new blends in quality when processed correctly.

- Chemical recycling yields high-quality fiber but is costly and rare.

- Mechanical recycling is common and effective; slight initial quality differences are compensated by thicker yarn or fabric.

- Blending recycled polyester with cotton or nylon maintains fabric strength and versatility.

- Thorough cleaning of recycled materials ensures purity without harmful chemicals.

Is recycled cotton/polyester blend as strong as new cotton/polyester?

Yes, by the time you buy it, recycled blends match the strength of new ones. Manufacturers often use thicker yarn or fabric to ensure durability is similar.

Does the recycling method affect the quality of polyester?

Chemical recycling yields higher quality fibers, but it’s costly and rare. Most recycled polyester uses mechanical recycling, which produces slightly lower quality fibers but works well after adjustments.

How do manufacturers compensate for differences in recycled fiber quality?

They use thicker yarns or heavier fabrics. This balances out any minor quality drop from recycled fibers, keeping abrasion and tensile strength on par with virgin blends.

Are recycled cotton/polyester fabrics blended differently than new fabrics?

The blending process is similar for both. Polyester yarn may be mixed with cotton or nylon to create a desired fabric feel and thickness.

Is the recycled polyester cleaned thoroughly before reuse?

Yes. It’s washed with water, soap, and sometimes mild sterilizers. This removes contaminants without harmful chemicals, ensuring safe and clean recycled fiber.

Leave a Comment