Scientific Glassblower here. What can I do for ya, r/chemistry?

Scientific glassblowing remains a specialized craft essential to modern chemistry and scientific research. This niche art involves creating, customizing, and repairing glassware used in laboratories worldwide. Glassblowers supply tailored apparatus like Soxhlet extractors, Schlenk flasks, air-free cuvettes, and quartz parts. Their work supports experiments requiring precise and durable glass instruments. Although scientific glassblowing faces extinction risk, it continues to attract interest for its technical and artistic merits. This article explores the practice, career paths, product offerings, and challenges associated with this valuable profession.

The Art and Practice of Scientific Glassblowing

Scientific glassblowing merges artistry, precision, and chemistry knowledge. It is often called a dying art because fewer people train in it today, yet its contributions remain indispensable. Glassblowers manipulate glass tubing and quartz under high heat, shaping vessels that withstand harsh laboratory conditions.

Many users express admiration for this craft, emphasizing its need for preservation. The technical skill required blends glass knowledge, manual dexterity, and understanding of chemical applications.

Entry into the Field

- Career routes vary: Some glassblowers start as scientists, others from artisan backgrounds.

- Many develop the trade through apprenticeships or specialized workshops.

- Long-time practitioners often focus on quartz parts due to their chemical and thermal resistance.

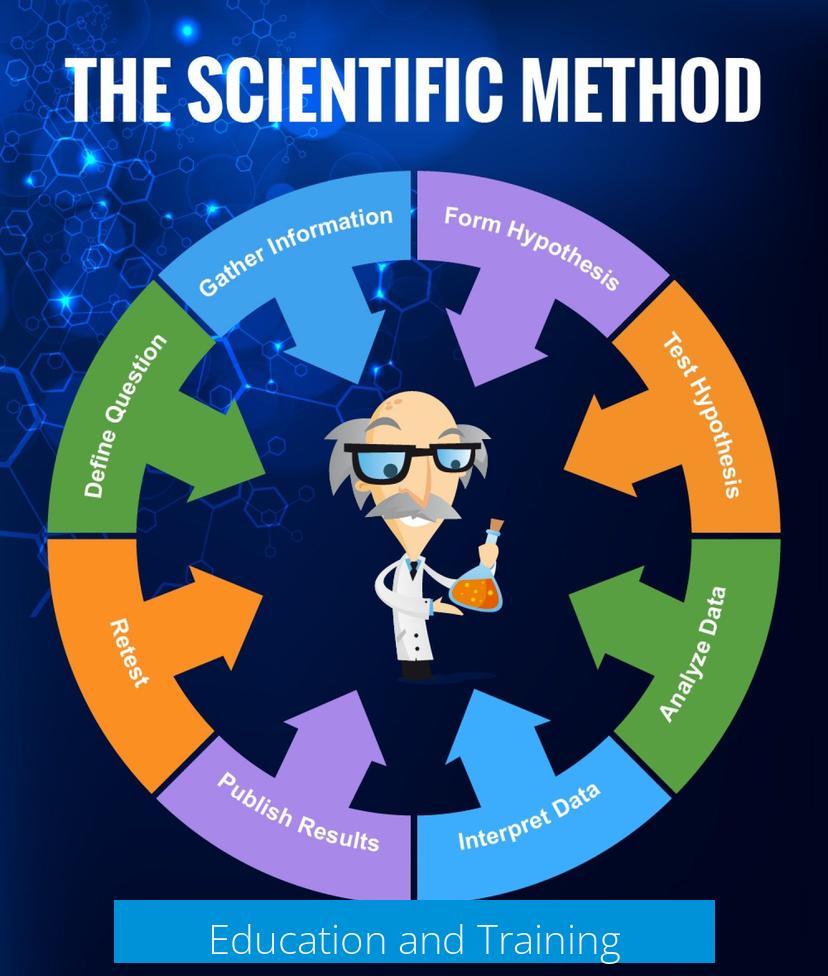

Education and Training

Formal training is limited but includes certificate or associate degree programs in scientific or artistic glassblowing. Comprehensive introductory texts exist, addressing glass properties and techniques.

Because it is a specialized craft, many learn on the job or via mentorship. The field lacks widespread academic programs, increasing its endangered status.

Products and Services Provided by Scientific Glassblowers

Typical Product Range

- Soxhlet extractors for solvent extraction processes

- Condensers and cooling apparatus

- Custom cuvettes, notably air-free quartz types for spectroscopy

- Schlenk flasks for inert atmosphere chemistry

- Büchner funnels with filtration disks for vacuum filtrations

- Chromatography columns with/without filtration supports

Glassblowers often cater to universities, research institutions, and specialized hobbyists. Sales vary widely; some offer a few specialized items, while others customize per client specifications.

Custom and Specialty Items

Many requests involve repairing or manufacturing unique pieces, such as:

- Quartz tubes and cuvettes tolerating high temperatures and corrosive chemicals

- Difficult air-free cuvettes needing hermetic sealing

- Restoring broken glass thermometers or cracked quartz components

Clients sometimes inquire about selling surplus quartz tubes or other raw materials.

Market Focus and Business Recommendations

Profit margins often improve with complicated custom pieces given their unique nature and technical demands. Experts advise focusing on:

- High-vacuum and gas manifold systems

- Schlenk line-compatible glassware

- Reliable, high-quality filtration funnels and columns

Studying established company catalogs like Chemglass helps identify successful product designs and market trends. These catalogs highlight quality and consistent manufacturing.

Shipping and Logistics Considerations

Shipping delicate glassware, especially internationally, poses challenges. Glassblowers receive questions regarding:

- Shipment to overseas labs, including Europe

- Costs and packaging to avoid breakage

Reliable communication channels such as emails or messaging help manage orders and customer inquiries globally.

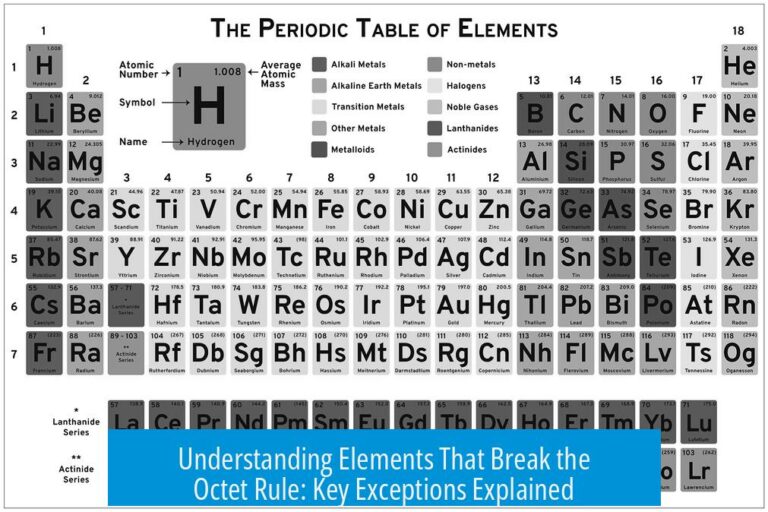

Technical Challenges in Scientific Glassware Use and Repair

Common Issues

One frequent problem involves quartz dust depositing on cuvette surfaces. This accumulation scatters light, compromising optical clarity and experimental accuracy. Experts look for methods to minimize or clean this contamination without damaging the glass.

Repair Expertise

Cracks or breaks in quartz parts are common due to the brittle yet valuable nature of this material. Skilled glassblowers specialize in repairing or fabricating replacements. Restoration extends glassware lifespans, reduces costs, and ensures experimental continuity.

Community Engagement and Growing Interest

Support and Advice

Scientific glassblowers engage actively with researchers, providing guidance on equipment selection and maintenance. While not all users have immediate orders, many bookmark resources for future needs.

Constructive dialogue often occurs via email or dedicated forums, fostering understanding of evolving synthetic organic chemistry requirements and glassware innovations.

Fostering Future Practitioners

Interest in preserving this craft encourages newcomers to explore apprenticeships or study materials. The scarcity of formal programs heightens the need for mentorship and community support to ensure knowledge transfer.

Key Takeaways

- Scientific glassblowing combines artistry and chemistry to create specialized lab glassware essential for research.

- The craft is endangered but remains crucial, attracting interest from scientists and artisans alike.

- Career entry often involves apprenticeships; formal programs are rare but valuable.

- Products range from standard laboratory glassware to custom quartz parts and repairs.

- Focus on high-vacuum and inert atmosphere glassware offers good market potential.

- Technical challenges include contamination by quartz dust and repairing brittle glass components.

- International sales require careful packaging and communication to ensure product safety and client satisfaction.

- Community interaction fosters knowledge sharing and supports the craft’s survival.

Scientific glassblowing continues as an indispensable yet vulnerable practice. Its blend of skill, science, and craftsmanship positions it uniquely in the chemistry ecosystem. Supporting and understanding this art ensures reliable glass instruments that advance scientific discovery.

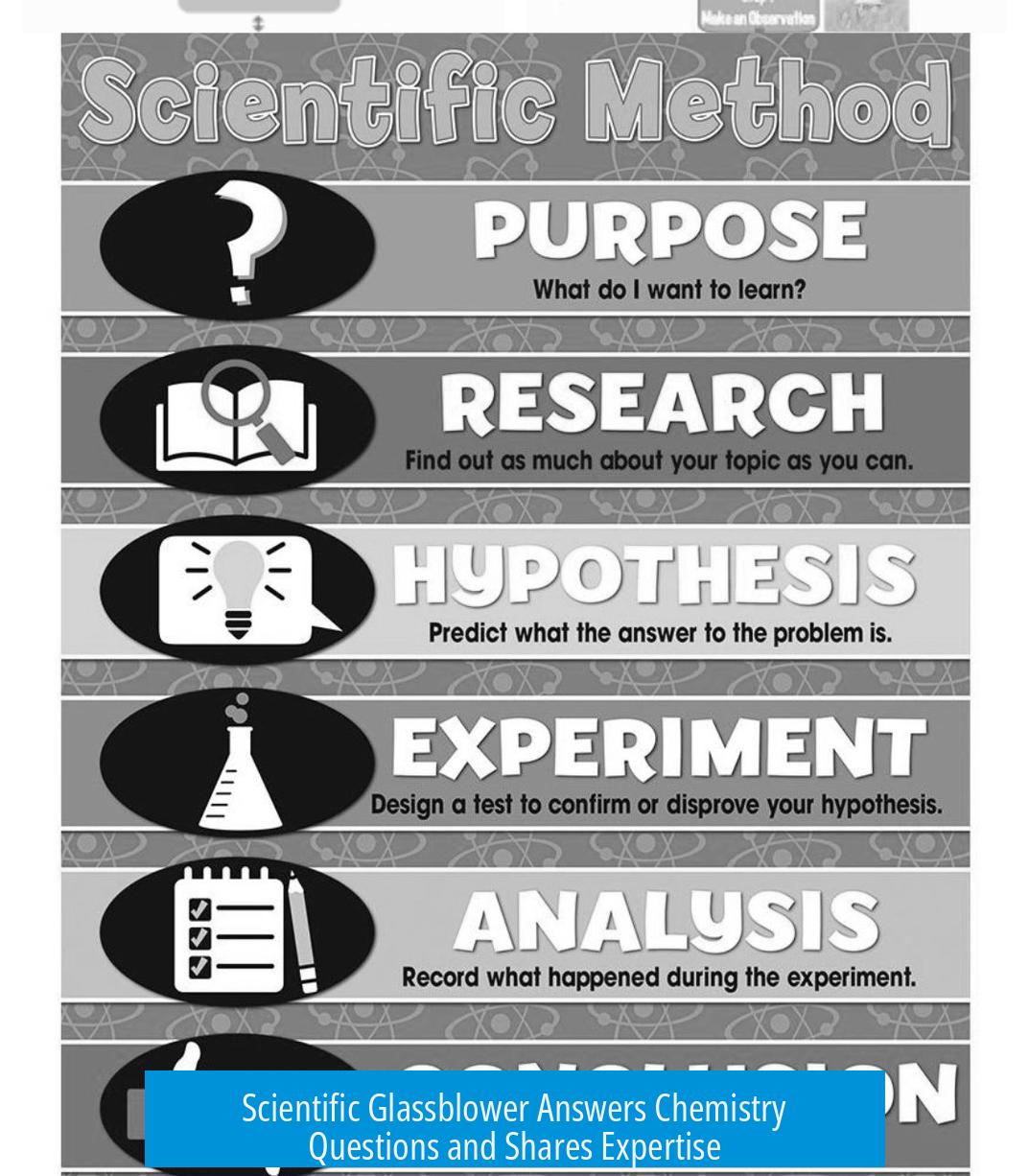

What kind of custom glassware can a scientific glassblower create or repair?

They make custom pieces like air-free cuvettes, Schlenk flasks, and chromatography columns. Repairs often include fixing cracked or broken quartz parts and restoring delicate glass thermometers.

Are there specific training programs or certifications for becoming a scientific glassblower?

Certificate and associate degree programs exist but are rare. Many learn through apprenticeships or on-the-job training. Books and resources are also helpful for beginners interested in the craft.

Who typically buys scientific glassware and do you ship internationally?

Customers range from university labs to industrial researchers. Some hobbyists also buy specialized pieces. Shipping to Europe and other regions is possible, but rates and logistics vary.

How do glassblowers handle issues like quartz dust deposition on glassware?

Quartz dust on cuvettes can reduce clarity. Glassblowers have techniques to clean or reprocess these surfaces to restore transmission quality for accurate measurements.

What advice do glassblowers give about product focus in this niche market?

They suggest concentrating on high-demand items with good profit margins, like air-free vacuum glassware, specialized filtration funnels, and chromatography columns modeled after top industry designs.

Leave a Comment