How is CO2 Obtained and Placed in Tanks?

Carbon dioxide (CO2) is primarily obtained as a byproduct in various industrial processes and then captured, purified, compressed, and stored in tanks for distribution and use. The process involves sourcing CO2 from hydrogen and ammonia production, using absorption and adsorption techniques for capture, and compressing the purified gas into high-pressure tanks.

Carbon dioxide (CO2) is primarily obtained as a byproduct in various industrial processes and then captured, purified, compressed, and stored in tanks for distribution and use. The process involves sourcing CO2 from hydrogen and ammonia production, using absorption and adsorption techniques for capture, and compressing the purified gas into high-pressure tanks.

Industrial Sources of CO2

One of the main sources of carbon dioxide is the industrial production of hydrogen and ammonia. These processes start with natural gas, mainly methane, reacting with steam. In steam reforming and the water gas shift reaction, CO2 forms as a byproduct. This CO2 often meets food-grade standards and is used in beverages and animal stunning.

Other sources include burning fossil fuels, brewing, steel and concrete production, and the quicklime industry, where roasting calcite releases CO2. These varied origins provide bulk carbon dioxide that can be captured and processed.

CO2 Capture and Purification

Captured exhaust gases containing CO2 pass through absorption systems, such as tanks filled with monoethanolamine (MEA). MEA selectively absorbs CO2 when the gas is hot and releases it when cooled. This absorption-desorption cycle allows for CO2 extraction with high purity.

Another advanced method is pressure/temperature swing adsorption. Gas streams are treated and then exposed to cycles of pressure and temperature changes, enabling the separation of high-purity CO2, ready for compression and storage.

Ammonia plants, which require CO2 removal to protect catalysts, typically install compressors and bottling units. Since CO2 must be separated anyway, capturing and compressing it onsite is cost-effective. The separation cost can be low, often under $5 per tonne of CO2.

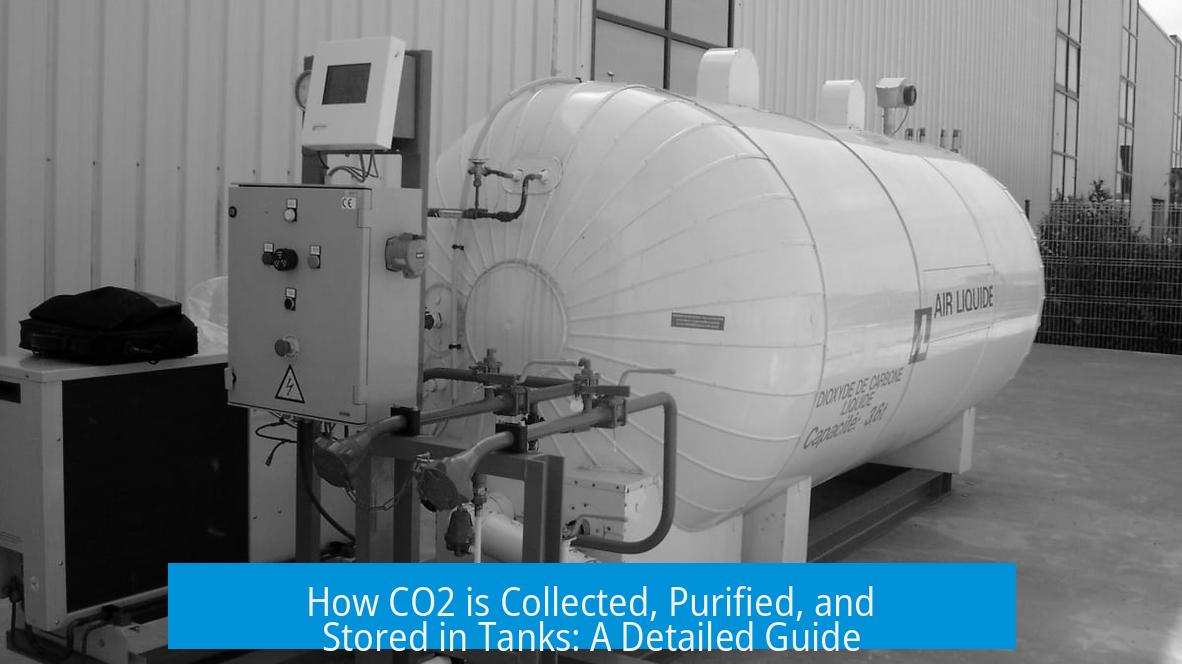

Compression and Storage of CO2

The purified CO2 is pressurized and filled into storage tanks or tanker trucks for transport. This pressurization is crucial for safe handling and efficient storage. CO2 is also converted into dry ice or placed in soda tanks in beverage industries. Facilities typically maintain a section dedicated to filling cylinders and tanker trucks.

Welding supply stores and industrial gas suppliers commonly stock CO2 cylinders for various applications. Distribution logistics, especially transportation costs, significantly affect the final price of CO2.

Summary of Key Points

- CO2 mostly comes from hydrogen, ammonia production, and industrial processes involving fossil fuels.

- Absorption using MEA and pressure/temperature swing adsorption are common purification methods.

- Ammonia plants often separate and compress CO2 as part of their process, offering cost-effective sources.

- Purified CO2 is compressed and stored in tanks or tankers for distribution.

- Transportation costs play a significant role in CO2 market pricing.

How is CO2 Obtained and Placed in Tanks? Unlocking the Invisible Gas Mystery

Carbon dioxide (CO2) doesn’t just float around freely waiting to be bottled. Instead, it’s carefully captured from industrial processes, purified, compressed, and then stuffed into tanks, ready for a host of uses—from fizzy drinks to feeding plants in greenhouses and even stunning poultry. But how exactly does this happen? Let’s unmask the journey of CO2 from industrial byproduct to tanked treasure.

First off, you might wonder, “Where does this CO2 actually come from?” It’s not conjured magically but results mainly as a byproduct from other chemical processes—particularly in hydrogen and ammonia production.

1. CO2’s Origins: The Industrial Footprint

Many processes produce CO2. Perhaps the most significant source is the production of hydrogen via steam reforming and the making of ammonia. Here’s the deal:

- The process starts with natural gas, mostly methane (CH4), reacting with water.

- This reaction produces hydrogen and CO2 among other things.

This CO2 is clean and food-grade, so it’s perfect for making your beer and soda bubbles fizz, or even gently stunning poultry at the slaughterhouse.

But that’s not all. Other big players include:

- Burning fossil fuels.

- Brewing operations.

- Steel and concrete production.

- Quicklime industry, which roasts calcite (a carbonate mineral) to produce calcium oxide and CO2.

So yes, all those smokestacks and kilns help release CO2, which we capture instead of letting it drift into the atmosphere.

2. Capturing CO2: From Smokestack to Storage

The big question: how do we capture CO2 so efficiently? Imagine things like giant gas filters. One cool, real-world method comes from a CO2 plant where the exhaust from burning natural gas passes through tanks filled with a chemical called MEA (monoethanolamine).

Here’s the magic twist:

- The hot exhaust gas loads the MEA solution with CO2.

- Then, cooling the solution releases pure CO2.

This process continually cycles—absorbing and releasing CO2.

Once you have the CO2 isolated, further purification happens through something called pressure/temperature swing adsorption. Fancy name, straightforward idea: switch the pressure or temperature to make CO2 stick to or release from a surface, ending up with almost pure gas.

In ammonia plants, this is even more strategic. Ammonia production needs to separate CO2 to protect metal catalysts from poisoning. Instead of letting the CO2 go to waste, companies compress it into tanks for sale. This clever dual use keeps costs low—around $5 per tonne of CO2.

Sourcing CO2 from natural gas or liquefied natural gas (LNG) production costs a bit more, around $5 to $15 per tonne, largely because transporting the heavy steel tanks adds extra expense.

3. Pressurizing and Filling: CO2 Joins the Tank Club

After separation and purification, CO2 is compressed to fit snugly inside sturdy tanks. The compression makes the gas denser and easier to transport and store.

In fact, at CO2 plants, there’s usually a busy filling section where tanks and even tanker trucks get loaded.

- From here, CO2 heads out to facilities that make dry ice or fill up soda tanks.

- If you’re a welder or a craft soda maker, you can often pick up your fill at welding supply stores that carry CO2 cylinders.

4. A Quick Bit of CO2 History and Lessons Learned

Did you know there was a CO2 shortage in Europe back in summer 2018? Several ammonia plants were temporarily shut down for maintenance, cutting the supply sharply.

This shortage illustrated just how crucial these industrial processes are for continuous CO2 availability.

Also, personal experiences from industry insiders show the complexity behind getting CO2 ready for market. For example, working at a natural gas refining facility involved dealing with impurities and ensuring CO2 streams were pure and ready to be crammed into tanks.

5. Practical Tips: What Can You Learn From This?

- If you’re curious about CO2 supply locations, your local welding shop or industrial gas supplier is a great place to start.

- When buying CO2 cylinders, note that filling costs usually depend on tank size, purity, and delivery.

- Understanding the source of your CO2 (ammonia byproduct vs. natural gas processing) can indicate the quality and price.

Why be picky? Well, high-purity CO2 is essential for beverage carbonation, while lower purity may suffice for industrial uses such as welding.

6. Why Does This Matter?

CO2 is everywhere but capturing and storing it responsibly is critical to reduce emissions and support industries. By capturing CO2 from processes that produce it anyway, we’ve made a smart resource out of a waste product.

So next time you sip a fizzy drink, remember there’s a whole high-tech world behind that bubbly magic—starting from a chemical reaction, flowing through absorbers and compressors, right into a tank that makes life simply more refreshing.

Final Thoughts

CO2 isn’t just a gas drifting in the air—it’s a carefully captured, purified, and pressurized product with wide applications. Advances in capturing CO2 during hydrogen and ammonia production help keep costs down and supply steady. The process involves absorbing CO2 with chemicals like MEA, using pressure and temperature tricks to purify the gas, then compressing it into tanks for easy distribution. So many industries rely on this. Whether it’s making soda enjoyable or ensuring welding works smoothly, that tank of CO2 represents complex, clever engineering behind a seemingly simple gas.

And for the geeky enthusiasts reading this—ever wondered what it takes to keep your soda bubbly in hot summer? Or how a poultry farm safely and humanely manages animals? Now you have the answer, literally under pressure!

How is CO2 mainly obtained in industry?

CO2 is often a byproduct of hydrogen and ammonia production. It forms when natural gas reacts with steam in these processes. This CO2 is captured instead of vented and used for various applications.

What methods are used to capture and purify CO2?

One method uses chemical absorbents like MEA to capture CO2 from exhaust gases. Another method involves pressure and temperature swing adsorption to produce high purity CO2 streams.

How is CO2 stored once captured?

Captured CO2 is compressed and stored in high-pressure tanks. These tanks are then filled for distribution or used to create dry ice. Tanker trucks can also be filled for large transport.

Why is CO2 separation important in ammonia production?

CO2 must be removed to prevent catalyst poisoning during ammonia synthesis. Capturing it allows reuse or sale, reducing waste and emissions while supporting other industries.

What factors influence the cost of obtaining CO2?

The main cost drivers are the source of CO2 and transportation. Separation is often included in existing industrial processes, so transport of heavy CO2 bottles or tanks is a significant expense.

Leave a Comment