Processing a Jar Full of Catalytic Converter Platinum with White Fluffy Stuff

Yes, it is possible to process the platinum contained in a jar from catalytic converters that has white fluffy material, but it requires specialized methods due to the composition and properties of platinum and the associated materials.

Challenges in Processing Platinum

Platinum’s very high melting point poses a major challenge. It requires extremely high temperatures, achievable only with equipment such as an oxygen torch or an arc furnace, to melt and separate it from other materials.

The precious metals content in catalytic converters is typically very low. For example, a vehicle catalytic converter may contain less than 10 grams of platinum and often closer to 3 grams. This low yield makes small-scale processing difficult and generally unprofitable.

Understanding the White Fluffy Material

The white fluffy substance commonly found in catalytic converter remnants is usually zeolite or certain porous rocks. Zeolite acts as a support material in converters but does not contain valuable metals. This material must be separated from the actual precious metals during processing.

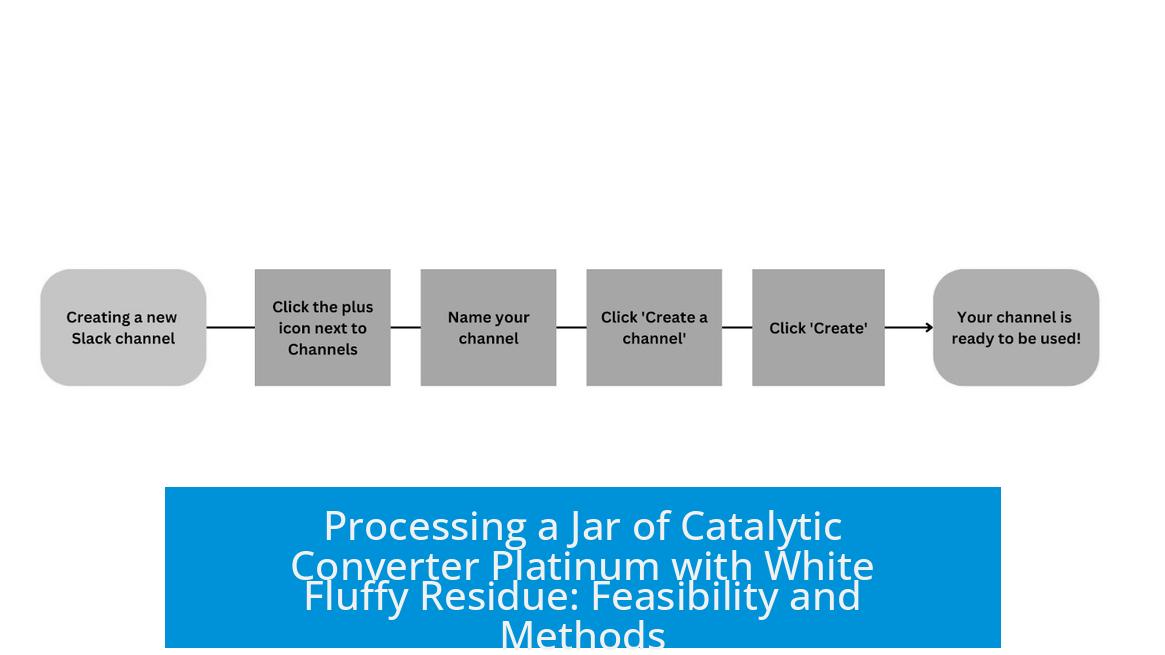

Processing Methods and Feasibility

- High-temperature smelting: Specialized furnaces that exceed platinum’s melting point (~1768°C) are necessary.

- Chemical leaching: Some processes use aqua regia or other strong acids to dissolve platinum, but these require careful handling and waste management.

- Commercial scale: Due to low metal concentration, profitability appears only when processing large amounts of material.

For small quantities, selling the catalytic converter scraps to specialized scrap yards is often more practical. Such yards pay cash for scrap containing platinum, typically $100 to $300 depending on the content and market conditions.

Next Steps and Recommendations

- Identify reliable local scrap metal recyclers that accept catalytic converter materials.

- Research smelting techniques via educational resources or professional metallurgical services.

- Consider the scale: small quantities usually do not justify investment in specialized equipment.

“You’d need a LOT of heat like an oxygen torch or an arc furnace to get that stuff to melt.”

Summary

- Platinum’s high melting point demands specialized high-heat equipment.

- White fluffy material is mostly zeolite, without precious metals.

- Low platinum content makes small-scale recovery inefficient.

- Commercial recycling yards are better options for small amounts.

- Smelting or chemical recovery requires expertise and scale.

What is the white fluffy stuff in my jar with catalytic converter platinum?

The white fluffy stuff is mostly zeolite or cheap rocks mixed in. These materials are common and not valuable. They are part of the ceramic substrate of the catalytic converter.

Can I melt the platinum with the white fluffy material still in the jar?

Platinum requires very high heat to melt, like using an oxygen torch or arc furnace. The white fluffy materials usually burn away or melt at lower temperatures, leaving the platinum behind.

Is it worth processing a small jar of catalytic converter platinum at home?

The amount of precious metals is very low in small samples. Without a commercial setup, it’s unlikely to be profitable or efficient to process small jars on your own.

How should I process this jar to recover platinum properly?

Most recommend selling the material to a scrap metal yard. They have the proper equipment to extract and refine the platinum safely and effectively.

Are there resources to learn how to smelt platinum from catalytic converters?

You can find videos online, especially on YouTube, showing how to smelt platinum. These might help you understand the process better before attempting any recovery.

Leave a Comment